Open source, modular bench power supply

Here’s a neat bench power supply design from a Hackaday user which offers very interesting features such as software calibration, programmatic control via USB Raw HID, etc at an affordable price. While this is still an ongoing project, the author defines his final goals of this project as:

- Modular power supply from 1 to 6 channels (I am planning on having 4: 3x positive, 1x negative)

- Each channel can independently be set from 0-12V (for positive channels) or -12-0V (for negative channels), and the output can go all the way to 0.

- Configurable set points for voltage and max current for each channel

- Actual readings for voltage and current for each channel

- Low cost – it’s not as cheap as scrapping an ATX power supply (which is what I am using today), but the extra features such as current limiting should more than make up the extra cost.

- Active (fan) cooling combined with heat sinks to support sustained high current loads

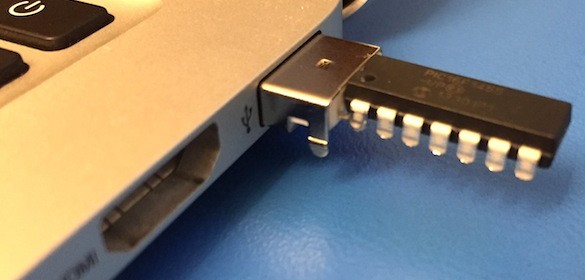

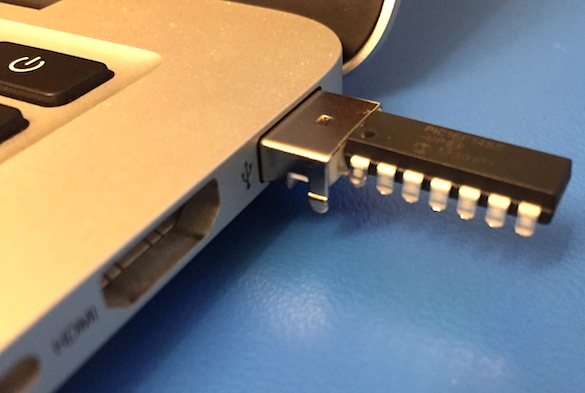

- USB control (voltage and current set points), logging of actual voltage / current readings, and computer-based calibration.

- The ability to use potentiometers for voltage / current set points instead of a microcontroller, if desired (each channel has four analog I/Os: Voltage and Current setpoints, and Voltage and Current sense outputs. All of these are in the range of 0-5V, allowing easy control from either a potentiometer or a DAC.