Rotary dial phone gets GSM upgrade

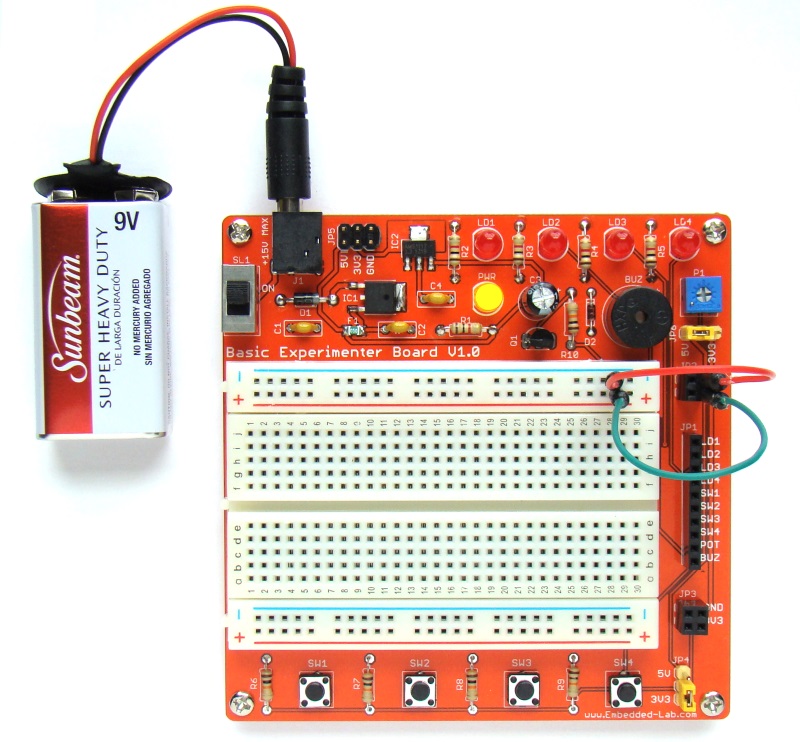

I found this nice Instructable from Acmecorporation on upgrading an old-school rotary dial telephone to a GSM phone using Arduino and a SIM900 GSM shield, while preserving the classical ringing sound, sluggish rotating dialer, and a heavy handset.

These kind of telephone cannot be used now days due to incompatibility between pulse and tone dialing. Before trash it i ask to myself: how can i transform it? My aim was to replay old feelings: classical ringing sound, rotating dialer and a heavy comfortable handset. Then i decided to relive that and so, in this instructables, i’ll show how to transform a rotary dialer telephone to GSM telephone using Arduino and a SIM900 GSM shield.

From late 60’s till 1985, the only Italian telephone company (SIP) furnished to each contract subscriber a basic rotary dialer telephone Siemens AUSO brand named “bigrigio”, that translated means “double-grey”. Expensive calls and slow number dialing didn’t help to people communications like today.