More on TI MSP430s

|

|

This post is a sequel of the first post on TI MSP430 micros here.

Low Power Modes (LPM)

From the smartwatches in our wrists to the vehicles we use for transportation, many modern electronic gadgets and gizmos are battery-powered. Some are even dependent on renewable energy sources like solar energy. In such devices, there is always an inherent energy crisis and so saving energy is a must in such designs for prolonged usage. At present there is hardly any microcontroller in the market that does not come equipped with energy-saving schemes or low power modes of operation. MSP430s were mainly designed for battery-backed instruments and it is no surprise that they come loaded with the some of the best possible energy-saving mechanisms.

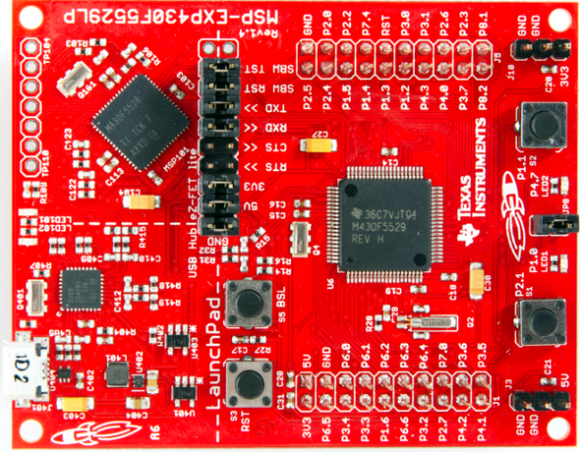

There six modes of operation of which five are low power modes. These are as follows:

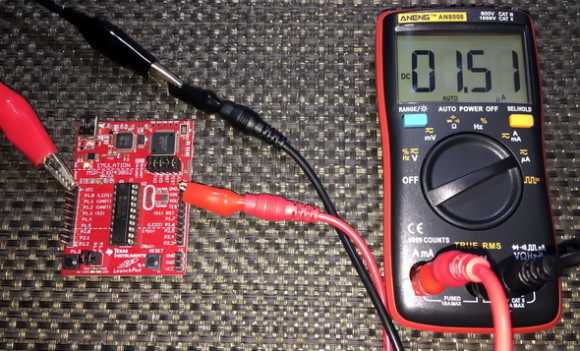

Of these six modes, three modes are mostly used – Active Mode (AM), LPM0 and LPM3. In Active Mode, the typical self-consumption of a MSP430 device is roughly about 300µA with nothing connected to it. In LPM0 the self-consumption is about a third of active mode while in LPM3, this consumption is just about 1µA. These figures tell us how much energy efficient MSP430s are.

Entering and exiting LPM is easy in terms of coding. However, the most common question that coders face with LPMs is how to get back to active mode or some other low power mode from a given low power mode. Well, it is pretty simple and it is accomplished with interrupts. It is up to coders to decide how to manage interrupts, clock sources and what do to after waking up from a LPM condition. Note that in LPMs, the CPU is disabled and so any task that requires CPU’s intervention is stalled. Since the CPU and some clocks are halted in LPMs, don’t even think that the tasks depending on them will be magically done. For instance, if a code has entered LPM3 and a timer is being driven with SMCLK, we should not expect it to tick because in LPM3, SMCLK is turned off. Organizing the code in a decent and well-planned manner is the secret behind successfully implementing LPMs.

Code Example

#include <msp430.h>

#include "delay.h"

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

#pragma vector = PORT1_VECTOR

__interrupt void PORT1_ISR_HOOK(void)

{

LPM2_EXIT;

P1OUT |= BIT6;

P1IFG = 0x00;

}

void main(void)

{

unsigned char s = 0;

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();

/* initialize Config for the MSP430 WDT+ */

WDTplus_graceInit();

while(1)

{

for(s = 0; s < 9; s++)

{

P1OUT ^= BIT0;

delay_ms(160);

}

P1OUT &= ~BIT6;

LPM2;

};

}

void GPIO_graceInit(void)

{

/* USER CODE START (section: GPIO_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: GPIO_graceInit_prologue) */

/* Port 1 Output Register */

P1OUT = BIT3;

/* Port 1 Direction Register */

P1DIR = BIT0 | BIT6;

/* Port 1 Resistor Enable Register */

P1REN = BIT3;

/* Port 1 Interrupt Edge Select Register */

P1IES = BIT3;

/* Port 1 Interrupt Flag Register */

P1IFG = 0;

/* Port 1 Interrupt Enable Register */

P1IE = BIT3;

/* Port 2 Output Register */

P2OUT = 0;

/* Port 2 Port Select Register */

P2SEL &= ~(BIT6 | BIT7);

/* Port 2 Direction Register */

P2DIR = 0;

/* Port 2 Interrupt Edge Select Register */

P2IES = 0;

/* Port 2 Interrupt Flag Register */

P2IFG = 0;

/* USER CODE START (section: GPIO_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: GPIO_graceInit_epilogue) */

}

void BCSplus_graceInit(void)

{

/* USER CODE START (section: BCSplus_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: BCSplus_graceInit_prologue) */

/*

* Basic Clock System Control 2

*

* SELM_0 -- DCOCLK

* DIVM_0 -- Divide by 1

* ~SELS -- DCOCLK

* DIVS_0 -- Divide by 1

* ~DCOR -- DCO uses internal resistor

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

BCSCTL2 = SELM_0 | DIVM_0 | DIVS_0;

if (CALBC1_1MHZ != 0xFF)

{

/* Follow recommended flow. First, clear all DCOx and MODx bits. Then

* apply new RSELx values. Finally, apply new DCOx and MODx bit values.

*/

DCOCTL = 0x00;

BCSCTL1 = CALBC1_1MHZ; /* Set DCO to 1MHz */

DCOCTL = CALDCO_1MHZ;

}

/*

* Basic Clock System Control 1

*

* XT2OFF -- Disable XT2CLK

* ~XTS -- Low Frequency

* DIVA_0 -- Divide by 1

*

* Note: ~XTS indicates that XTS has value zero

*/

BCSCTL1 |= XT2OFF | DIVA_0;

/*

* Basic Clock System Control 3

*

* XT2S_0 -- 0.4 - 1 MHz

* LFXT1S_2 -- If XTS = 0, XT1 = VLOCLK ; If XTS = 1, XT1 = 3 - 16-MHz crystal or resonator

* XCAP_1 -- ~6 pF

*/

BCSCTL3 = XT2S_0 | LFXT1S_2 | XCAP_1;

/* USER CODE START (section: BCSplus_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: BCSplus_graceInit_epilogue) */

}

void System_graceInit(void)

{

/* USER CODE START (section: System_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: System_graceInit_prologue) */

/* Clear oscillator fault flag with software delay */

do

{

// Clear OSC fault flag

IFG1 &= ~OFIFG;

// 50us delay

__delay_cycles(50);

} while (IFG1 & OFIFG);

/*

* SR, Status Register

*

* ~SCG1 -- Disable System clock generator 1

* ~SCG0 -- Disable System clock generator 0

* ~OSCOFF -- Oscillator On

* ~CPUOFF -- CPU On

* GIE -- General interrupt enable

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

__bis_SR_register(GIE);

/* USER CODE START (section: System_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: System_graceInit_epilogue) */

}

void WDTplus_graceInit(void)

{

/* USER CODE START (section: RTC_B_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: RTC_B_graceInit_prologue) */

/*

* WDTCTL, Watchdog Timer+ Register

*

* WDTPW -- Watchdog password

* WDTHOLD -- Watchdog timer+ is stopped

* ~WDTNMIES -- NMI on rising edge

* ~WDTNMI -- Reset function

* ~WDTTMSEL -- Watchdog mode

* ~WDTCNTCL -- No action

* ~WDTSSEL -- SMCLK

* ~WDTIS0 -- Watchdog clock source bit0 disabled

* ~WDTIS1 -- Watchdog clock source bit1 disabled

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

WDTCTL = WDTPW | WDTHOLD;

/* USER CODE START (section: RTC_B_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: RTC_B_graceInit_epilogue) */

}

Simulation

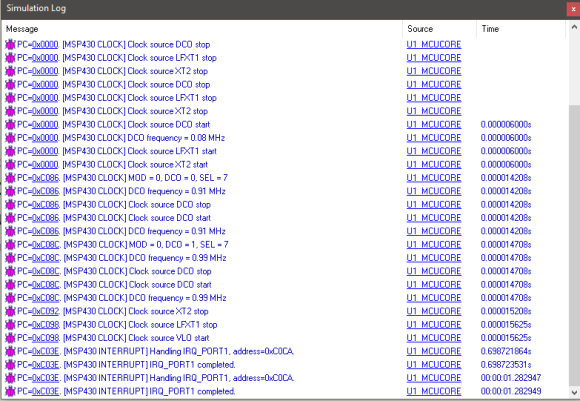

The simulation log of Proteus shown below shows when the internal oscillators started and stopped. These indicate LPM and AM states.

Explanation

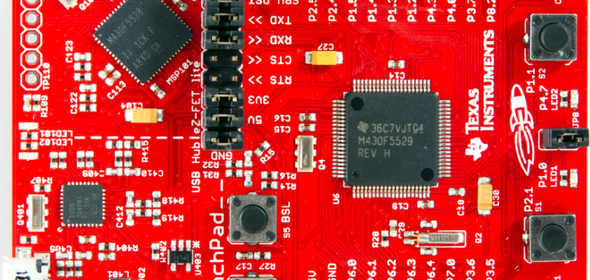

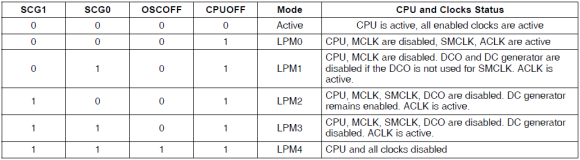

This is a pretty straight example. The code here works by first flashing the Launchpad board’s red LED for some time. During this time the MSP430 is running in active mode. After the flashing is over, the MP430 micro enters LPM2 state. Note that in LPM2 state all except the DC generator and ACLK are turned off. At this stage to wake up and exit LPM2, an interrupt is needed. Here this interrupt is generated by the external interrupt caused by pressing the Launchpad board’s user button. In the interrupt service routine (ISR), LPM2 is left and is indicated by a brief flash from the Launchpad board’s green LED. After executing the ISR, the code returns to main function and the process repeats again.

Note that for LPMs, there is no segment in Grace and LPM code definitions can be found in device’s header files.

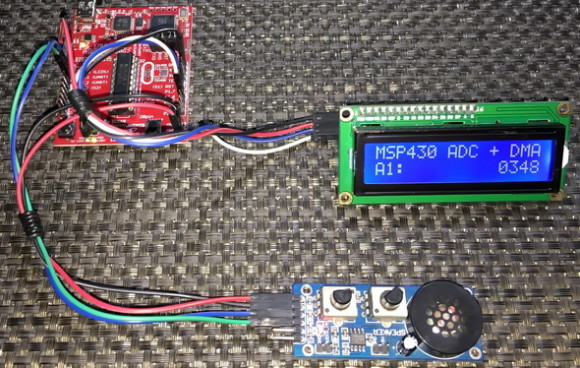

Demo

Internal Flash Memory

In some applications, there are some very important data that we wish to retain in our target device even when it is powered down. For such purposes we need a nonvolatile memory. Like many modern micros of today’s market, MSP430s do not contain any separate EEPROM memory or battery-backed nonvolatile memory. For storing data like calibration data, settings, etc. that we would have saved in EEPROM memories, we can use the internal flash memory of our MSP430 devices. Though it may sound difficult and challenging, it is not so. However, we need to be very careful about storage locations as such that we don’t accidentally use locations where application codes reside.

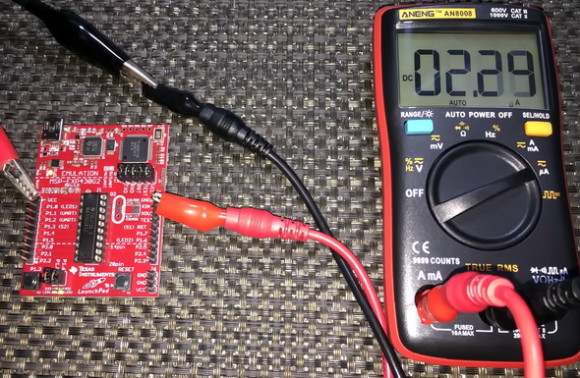

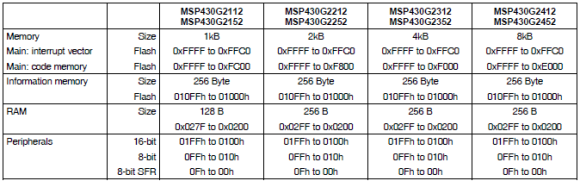

Shown below is a flash memory map example of a MSP430G2xxx device.

Note that there are four segments labelled A through D. These are the locations that we will be using for data storage and are called information memory. The rest is code space. We can also use the code space too but the code space has 512-byte segment size compared to 64-byte segment size of information memory. Now why is it so important to use information memory space instead of code memory? This is because of its small segment size. During memory erase, we have to erase a full segment. Bit, byte and word level read-write operations can be done easily but erasing is not possible at these levels. Two separate segments can be used to emulate low level erase. When such mechanism is applied. One segment acts like a buffer while the other is used for actual storage. Wear-leveling may optionally be applied. However, these processes add delays and extra cosing.

Segment A is a very important segment as it stores important internal calibration data like DCO frequency variables, etc. Thus, it is protected and locked separately. It will be wise to leave it and use the other three segments of information memory space to store data.

Code Example

#include <msp430.h>

#include "delay.h"

#include "SW_I2C.h"

#include "PCF8574.h"

#include "lcd.h"

void Flash_graceInit(void);

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

void lcd_print(unsigned char x_pos, unsigned char y_pos, unsigned char value);

void Flash_Erase(unsigned int address);

void Flash_Write_Char(unsigned int address, char value);

char Flash_Read_Char(unsigned int address);

void Flash_Write_Word(unsigned int address, unsigned int value);

unsigned int Flash_Read_Word(unsigned int address);

void main(void)

{

unsigned char value = 0x00;

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430F2xx Flash Memory Controller */

Flash_graceInit();

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();

/* initialize Config for the MSP430 WDT+ */

WDTplus_graceInit();

LCD_init();

LCD_clear_home();

LCD_goto(0, 0);

LCD_putstr("MSP430 Flash Ex.");

value = Flash_Read_Char(0x1000);

LCD_goto(0, 1);

LCD_putstr("WR: ---");

LCD_goto(9, 1);

LCD_putstr("RD:");

lcd_print(13, 1, value);

delay_ms(2000);

while(1)

{

if((P1IN & BIT3) == !BIT3)

{

while((P1IN & BIT3) == !BIT3);

Flash_Erase(0x1000);

Flash_Write_Char(0x1000, value);

lcd_print(13, 1, value);

P1OUT |= BIT0;

_delay_cycles(40000);

P1OUT &= ~BIT0;

}

delay_ms(20);

lcd_print(4, 1, value);

value++;

delay_ms(200);

};

}

void Flash_graceInit(void)

{

/* USER CODE START (section: Flash_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: Flash_graceInit_prologue) */

/*

* Flash Memory Control Register 2

*

* FSSEL_1 -- MCLK

* ~FN5 -- Flash controller clock divider bit 5

* FN4 -- Flash controller clock divider bit 4

* ~FN3 -- Flash controller clock divider bit 3

* FN2 -- Flash controller clock divider bit 2

* ~FN1 -- Flash controller clock divider bit 1

* FN0 -- Flash controller clock divider bit 0

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

FCTL2 = FWKEY | FSSEL_1 | FN4 | FN2 | FN0;

/* USER CODE START (section: Flash_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: Flash_graceInit_epilogue) */

}

void GPIO_graceInit(void)

{

/* USER CODE START (section: GPIO_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: GPIO_graceInit_prologue) */

/* Port 1 Output Register */

P1OUT = BIT3;

/* Port 1 Direction Register */

P1DIR = BIT0;

/* Port 1 Resistor Enable Register */

P1REN = BIT3;

/* Port 1 Interrupt Edge Select Register */

P1IES = 0;

/* Port 1 Interrupt Flag Register */

P1IFG = 0;

/* Port 2 Output Register */

P2OUT = 0;

/* Port 2 Direction Register */

P2DIR = 0;

/* Port 2 Interrupt Edge Select Register */

P2IES = 0;

/* Port 2 Interrupt Flag Register */

P2IFG = 0;

/* Port 3 Output Register */

P3OUT = 0;

/* Port 3 Direction Register */

P3DIR = 0;

/* USER CODE START (section: GPIO_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: GPIO_graceInit_epilogue) */

}

void BCSplus_graceInit(void)

{

/* USER CODE START (section: BCSplus_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: BCSplus_graceInit_prologue) */

/*

* Basic Clock System Control 2

*

* SELM_0 -- DCOCLK

* DIVM_0 -- Divide by 1

* ~SELS -- DCOCLK

* DIVS_0 -- Divide by 1

* ~DCOR -- DCO uses internal resistor

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

BCSCTL2 = SELM_0 | DIVM_0 | DIVS_0;

if (CALBC1_8MHZ != 0xFF) {

/* Adjust this accordingly to your VCC rise time */

__delay_cycles(100000);

// Follow recommended flow. First, clear all DCOx and MODx bits. Then

// apply new RSELx values. Finally, apply new DCOx and MODx bit values.

DCOCTL = 0x00;

BCSCTL1 = CALBC1_8MHZ; /* Set DCO to 8MHz */

DCOCTL = CALDCO_8MHZ;

}

/*

* Basic Clock System Control 1

*

* XT2OFF -- Disable XT2CLK

* ~XTS -- Low Frequency

* DIVA_0 -- Divide by 1

*

* Note: ~XTS indicates that XTS has value zero

*/

BCSCTL1 |= XT2OFF | DIVA_0;

/*

* Basic Clock System Control 3

*

* XT2S_0 -- 0.4 - 1 MHz

* LFXT1S_0 -- If XTS = 0, XT1 = 32768kHz Crystal ; If XTS = 1, XT1 = 0.4 - 1-MHz crystal or resonator

* XCAP_1 -- ~6 pF

*/

BCSCTL3 = XT2S_0 | LFXT1S_0 | XCAP_1;

/* USER CODE START (section: BCSplus_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: BCSplus_graceInit_epilogue) */

}

void System_graceInit(void)

{

/* USER CODE START (section: System_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: System_graceInit_prologue) */

/*

* SR, Status Register

*

* ~SCG1 -- Disable System clock generator 1

* ~SCG0 -- Disable System clock generator 0

* ~OSCOFF -- Oscillator On

* ~CPUOFF -- CPU On

* GIE -- General interrupt enable

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

__bis_SR_register(GIE);

/* USER CODE START (section: System_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: System_graceInit_epilogue) */

}

void WDTplus_graceInit(void)

{

/* USER CODE START (section: RTC_B_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: RTC_B_graceInit_prologue) */

/*

* WDTCTL, Watchdog Timer+ Register

*

* WDTPW -- Watchdog password

* WDTHOLD -- Watchdog timer+ is stopped

* ~WDTNMIES -- NMI on rising edge

* ~WDTNMI -- Reset function

* ~WDTTMSEL -- Watchdog mode

* ~WDTCNTCL -- No action

* ~WDTSSEL -- SMCLK

* ~WDTIS0 -- Watchdog clock source bit0 disabled

* ~WDTIS1 -- Watchdog clock source bit1 disabled

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

WDTCTL = WDTPW | WDTHOLD;

/* USER CODE START (section: RTC_B_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: RTC_B_graceInit_epilogue) */

}

void lcd_print(unsigned char x_pos, unsigned char y_pos, unsigned char value)

{

char chr = 0x00;

chr = ((value / 100) + 0x30);

LCD_goto(x_pos, y_pos);

LCD_putchar(chr);

chr = (((value / 10) % 10) + 0x30);

LCD_goto((x_pos + 1), y_pos);

LCD_putchar(chr);

chr = ((value % 10) + 0x30);

LCD_goto((x_pos + 2), y_pos);

LCD_putchar(chr);

}

void Flash_Erase(unsigned int address)

{

char *FlashPtr;

FlashPtr = (char *)address;

FCTL1 = FWKEY + ERASE; // Set Erase bit

FCTL3 = FWKEY; // Clear Lock bit

__bic_SR_register(GIE); // Disable Interrupts

*FlashPtr = 0; // Dummy write to erase Flash segment B

while((FCTL3 & BUSY) == BUSY); // Busy

__bis_SR_register(GIE); // Enable Interrupts

FCTL1 = FWKEY; // Lock

FCTL3 = FWKEY + LOCK; // Set Lock bit

}

void Flash_Write_Char(unsigned int address, char value)

{

char *FlashPtr = (char *)address;

FCTL1 = FWKEY + WRT; // Set WRT bit for write operation

FCTL3 = FWKEY; // Clear Lock bit

__bic_SR_register(GIE); // Disable Interrupts

*FlashPtr = value; // Save Data

while((FCTL3 & BUSY) == BUSY); // Busy

__bis_SR_register(GIE); // Enable Interrupts

FCTL1 = FWKEY; // Clear WRT bit

FCTL3 = FWKEY + LOCK; // Set LOCK bit

}

char Flash_Read_Char(unsigned int address)

{

char value = 0x00;

char *FlashPtr = (char *)address;

value = *FlashPtr;

return value;

}

void Flash_Write_Word(unsigned int address, unsigned int value)

{

unsigned int *FlashPtr = (unsigned int *)address;

FCTL1 = FWKEY + WRT; // Set WRT bit for write operation

FCTL3 = FWKEY; // Clear Lock bit

__bic_SR_register(GIE); // Disable Interrupts

*FlashPtr = value; // Save Data

while((FCTL3 & BUSY) == BUSY); // Busy

__bis_SR_register(GIE); // Enable Interrupts

FCTL1 = FWKEY; // Clear WRT bit

FCTL3 = FWKEY + LOCK; // Set LOCK bit

}

unsigned int Flash_Read_Word(unsigned int address)

{

unsigned int value = 0x0000;

unsigned int *FlashPtr = (unsigned int *)address;

value = *FlashPtr;

return value;

}

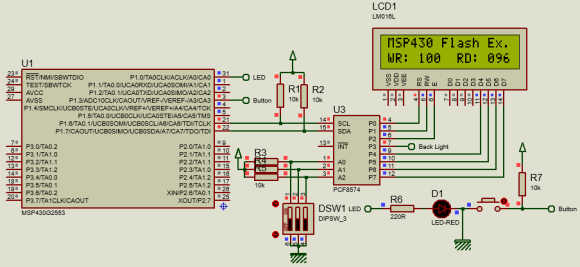

Simulation

Explanation

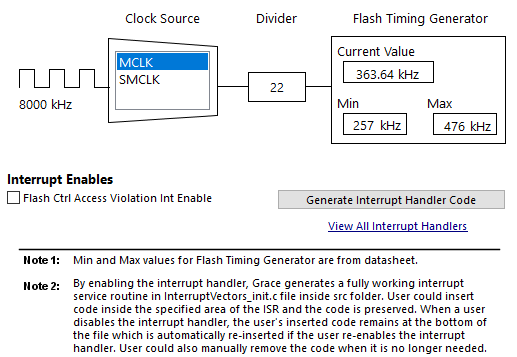

The flash memory module of MSP430s has an integrated controller that controls programming and erase operations. The controller has four registers, a timing generator, and a voltage generator to supply program and erase voltages.

Using Grace, we initialize the aforementioned:

FCTL2 = FWKEY | FSSEL_1 | FN4 | FN2 | FN0;

To write a byte, we need two things – memory location and the value we wish to write. This memory location is that piece of memory space where we wish to store the value.

void Flash_Write_Char(unsigned int address, char value)

{

char *FlashPtr = (char *)address;

FCTL1 = FWKEY + WRT; // Set WRT bit for write operation

FCTL3 = FWKEY; // Clear Lock bit

__bic_SR_register(GIE); // Disable Interrupts

*FlashPtr = value; // Save Data

while((FCTL3 & BUSY) == BUSY); // Busy

__bis_SR_register(GIE); // Enable Interrupts

FCTL1 = FWKEY; // Clear WRT bit

FCTL3 = FWKEY + LOCK; // Set LOCK bit

}

Firstly, the address of the memory location where data is to be stored is pointed out. Flash write process starts by setting the write bit, followed by removing the flash protection. Once these are done, all interrupts are temporarily disabled to avoid any accidental write or illegal operation. The value to be written is then pointed. Until the value is successfully written all other processes are halted. Once the value to be stored is successfully written, interrupts are enabled, the write bit is cleared and the flash lock is applied.

Reading the flash is simpler. We just have to point the location we wish to read.

char Flash_Read_Char(unsigned int address)

{

char value = 0x00;

char *FlashPtr = (char *)address;

value = *FlashPtr;

return value;

}

The process for erasing is similar to write processes. The only difference is Erase bit instead of Write bit.

void Flash_Erase(unsigned int address)

{

char *FlashPtr;

FlashPtr = (char *)address;

FCTL1 = FWKEY + ERASE; // Set Erase bit

FCTL3 = FWKEY; // Clear Lock bit

__bic_SR_register(GIE); // Disable Interrupts

*FlashPtr = 0; // Dummy write to erase Flash segment B

while((FCTL3 & BUSY) == BUSY); // Busy

__bis_SR_register(GIE); // Enable Interrupts

FCTL1 = FWKEY; // Lock

FCTL3 = FWKEY + LOCK; // Set Lock bit

}

The same read-write processes can also be applied to read/write word-level values.

The code demoed her works by reading the last data stored in the target flash location (0x1000) and incrementing a variable named value. Only this location is read and updated when the Launchpad board’s button is pressed.

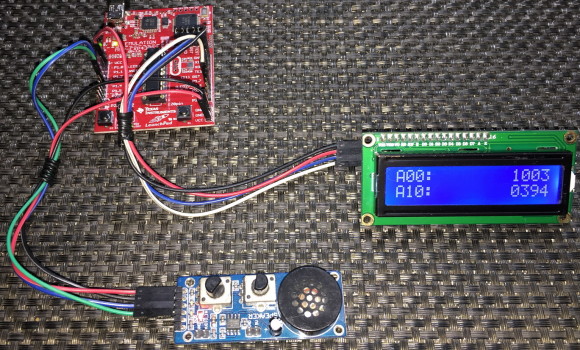

Demo

Time Delay Generation with Timer Compare-Match Feature

Time-bases and delays can be generated in many different ways, ranging from software techniques to using a dedicated hardware timer. Between software-based methods and hardware-based ones, the latter is more efficient and effective. This is because software-based methods rely on wasteful CPU-intensive loops and other resource-consuming processes. Hardware approaches for generating time-bases and delays are smart choices because the prime job of a timer is to count ticks or measure time. Yet within hardware-based methods, there are several techniques and tricks. We can choose between polling a free running timer or using interrupts to get things done in a more real-time sense. We have seen previously that we can use timer interrupts to time events. Here we will also see the same but this time compare-match interrupt is used instead of timer interrupt.

Code Example

#include <msp430.h>

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void Timer0_A3_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

#pragma vector = TIMER0_A0_VECTOR

__interrupt void TIMER0_A0_ISR_HOOK(void)

{

P1OUT ^= (BIT0 | BIT6);

__bic_SR_register_on_exit(LPM0_bits);

}

void main(void)

{

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 A3 Timer0 */

Timer0_A3_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();

/* initialize Config for the MSP430 WDT+ */

WDTplus_graceInit();

P1OUT |= BIT0;

P1OUT &= ~BIT6;

while(1)

{

__bis_SR_register(LPM0_bits);

};

}

void GPIO_graceInit(void)

{

/* USER CODE START (section: GPIO_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: GPIO_graceInit_prologue) */

/* Port 1 Output Register */

P1OUT = 0;

/* Port 1 Direction Register */

P1DIR = BIT0 | BIT6;

/* Port 1 Interrupt Edge Select Register */

P1IES = 0;

/* Port 1 Interrupt Flag Register */

P1IFG = 0;

/* Port 2 Output Register */

P2OUT = 0;

/* Port 2 Port Select Register */

P2SEL &= ~(BIT6 | BIT7);

/* Port 2 Direction Register */

P2DIR = 0;

/* Port 2 Interrupt Edge Select Register */

P2IES = 0;

/* Port 2 Interrupt Flag Register */

P2IFG = 0;

/* USER CODE START (section: GPIO_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: GPIO_graceInit_epilogue) */

}

void BCSplus_graceInit(void)

{

/* USER CODE START (section: BCSplus_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: BCSplus_graceInit_prologue) */

/*

* Basic Clock System Control 2

*

* SELM_0 -- DCOCLK

* DIVM_0 -- Divide by 1

* ~SELS -- DCOCLK

* DIVS_0 -- Divide by 1

* ~DCOR -- DCO uses internal resistor

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

BCSCTL2 = SELM_0 | DIVM_0 | DIVS_0;

if (CALBC1_1MHZ != 0xFF)

{

/* Follow recommended flow. First, clear all DCOx and MODx bits. Then

* apply new RSELx values. Finally, apply new DCOx and MODx bit values.

*/

DCOCTL = 0x00;

BCSCTL1 = CALBC1_1MHZ; /* Set DCO to 1MHz */

DCOCTL = CALDCO_1MHZ;

}

/*

* Basic Clock System Control 1

*

* XT2OFF -- Disable XT2CLK

* ~XTS -- Low Frequency

* DIVA_0 -- Divide by 1

*

* Note: ~XTS indicates that XTS has value zero

*/

BCSCTL1 |= XT2OFF | DIVA_0;

/*

* Basic Clock System Control 3

*

* XT2S_0 -- 0.4 - 1 MHz

* LFXT1S_0 -- If XTS = 0, XT1 = 32768kHz Crystal ; If XTS = 1, XT1 = 0.4 - 1-MHz crystal or resonator

* XCAP_1 -- ~6 pF

*/

BCSCTL3 = XT2S_0 | LFXT1S_0 | XCAP_1;

/* USER CODE START (section: BCSplus_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: BCSplus_graceInit_epilogue) */

}

void Timer0_A3_graceInit(void)

{

/* USER CODE START (section: Timer0_A3_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: Timer0_A3_graceInit_prologue) */

/*

* TA0CCTL0, Capture/Compare Control Register 0

*

* CM_0 -- No Capture

* CCIS_0 -- CCIxA

* ~SCS -- Asynchronous Capture

* ~SCCI -- Latched capture signal (read)

* ~CAP -- Compare mode

* OUTMOD_0 -- PWM output mode: 0 - OUT bit value

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

TA0CCTL0 = CM_0 | CCIS_0 | OUTMOD_0 | CCIE;

/* TA0CCR0, Timer_A Capture/Compare Register 0 */

TA0CCR0 = 49999;

/*

* TA0CTL, Timer_A3 Control Register

*

* TASSEL_2 -- SMCLK

* ID_3 -- Divider - /8

* MC_1 -- Up Mode

*/

TA0CTL = TASSEL_2 | ID_3 | MC_1;

/* USER CODE START (section: Timer0_A3_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: Timer0_A3_graceInit_epilogue) */

}

void System_graceInit(void)

{

/* USER CODE START (section: System_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: System_graceInit_prologue) */

/*

* SR, Status Register

*

* ~SCG1 -- Disable System clock generator 1

* ~SCG0 -- Disable System clock generator 0

* ~OSCOFF -- Oscillator On

* ~CPUOFF -- CPU On

* GIE -- General interrupt enable

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

__bis_SR_register(GIE);

/* USER CODE START (section: System_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: System_graceInit_epilogue) */

}

void WDTplus_graceInit(void)

{

/* USER CODE START (section: RTC_B_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: RTC_B_graceInit_prologue) */

/*

* WDTCTL, Watchdog Timer+ Register

*

* WDTPW -- Watchdog password

* WDTHOLD -- Watchdog timer+ is stopped

* ~WDTNMIES -- NMI on rising edge

* ~WDTNMI -- Reset function

* ~WDTTMSEL -- Watchdog mode

* ~WDTCNTCL -- No action

* ~WDTSSEL -- SMCLK

* ~WDTIS0 -- Watchdog clock source bit0 disabled

* ~WDTIS1 -- Watchdog clock source bit1 disabled

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

WDTCTL = WDTPW | WDTHOLD;

/* USER CODE START (section: RTC_B_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: RTC_B_graceInit_epilogue) */

}

Simulation

Explanation

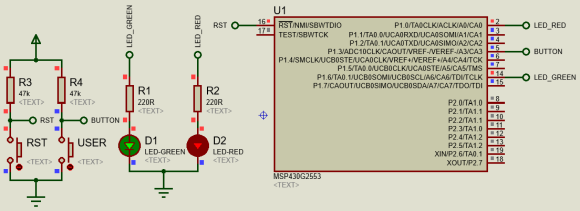

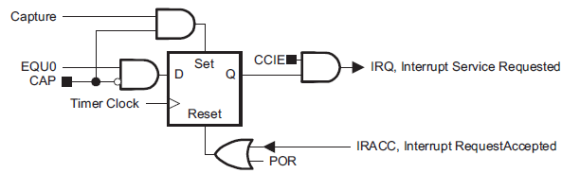

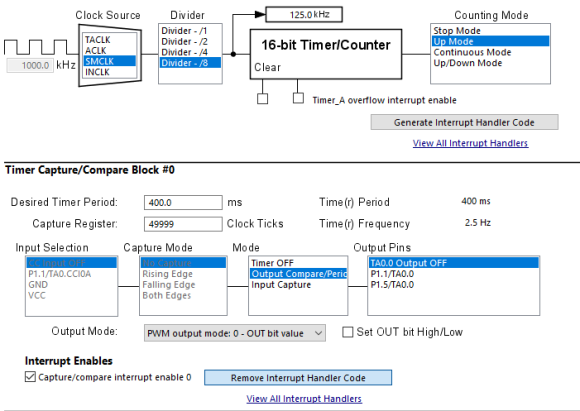

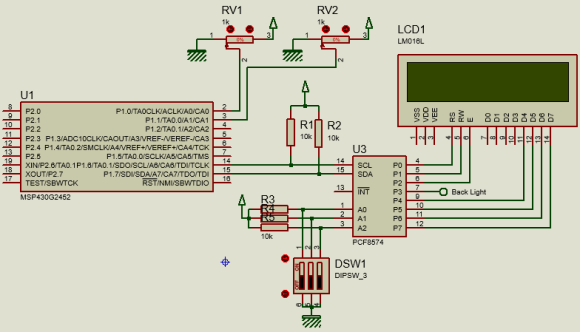

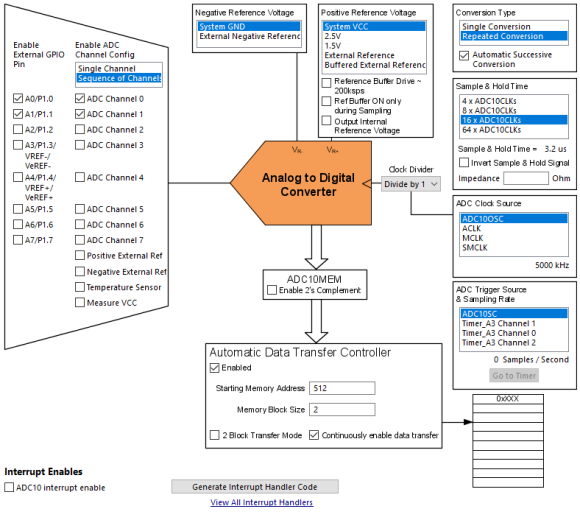

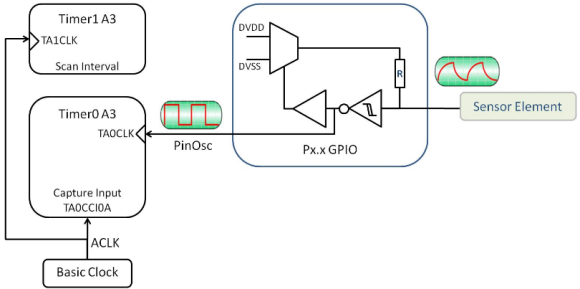

Timer0_A3 is set here for compare-match interval mode. In this mode, Timer0_A3’s settings are same as we would do for ordinary timer overflow interrupt. However, the key difference is the interrupt source. Note that in the diagram below timer overflow interrupt is not being used. Timer capture-compare interrupt is used instead.

The desire time period is set for 400ms or 2.5Hz. At every 400ms interval, a compare-match interrupt will occur. How this is done? Well the timer is set for up counting and it has an input clock of 125kHz – 1MHz SMCLK prescaled by 8.

void Timer0_A3_graceInit(void)

{

/* USER CODE START (section: Timer0_A3_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: Timer0_A3_graceInit_prologue) */

/*

* TA0CCTL0, Capture/Compare Control Register 0

*

* CM_0 -- No Capture

* CCIS_0 -- CCIxA

* ~SCS -- Asynchronous Capture

* ~SCCI -- Latched capture signal (read)

* ~CAP -- Compare mode

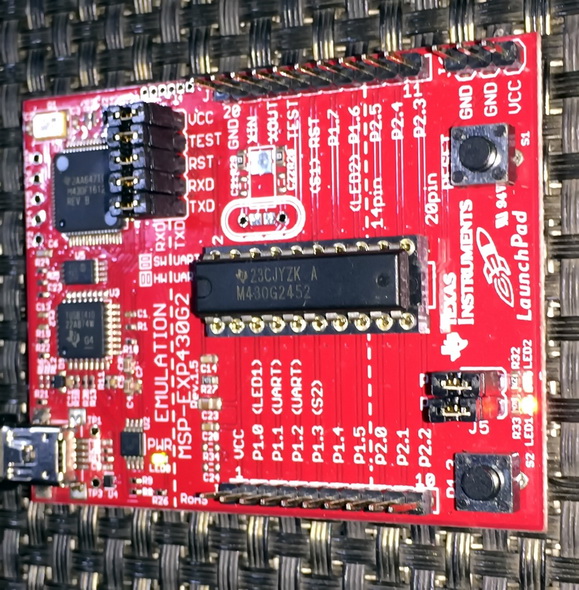

* OUTMOD_0 -- PWM output mode: 0 - OUT bit value

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

TA0CCTL0 = CM_0 | CCIS_0 | OUTMOD_0 | CCIE;

/* TA0CCR0, Timer_A Capture/Compare Register 0 */

TA0CCR0 = 49999;

/*

* TA0CTL, Timer_A3 Control Register

*

* TASSEL_2 -- SMCLK

* ID_3 -- Divider - /8

* MC_1 -- Up Mode

*/

TA0CTL = TASSEL_2 | ID_3 | MC_1;

/* USER CODE START (section: Timer0_A3_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: Timer0_A3_graceInit_epilogue) */

}

Inside the interrupt function, the LEDs of Launchpad board are toggled. Note that after the occurrence of the interrupt LPM0 is exited.

#pragma vector = TIMER0_A0_VECTOR

__interrupt void TIMER0_A0_ISR_HOOK(void)

{

P1OUT ^= (BIT0 | BIT6);

__bic_SR_register_on_exit(LPM0_bits);

}

In the main, there is no task and in it LPM0 is entered. Thus, the process is independent of the main and is energy efficient.

while(1)

{

__bis_SR_register(LPM0_bits);

};

Demo

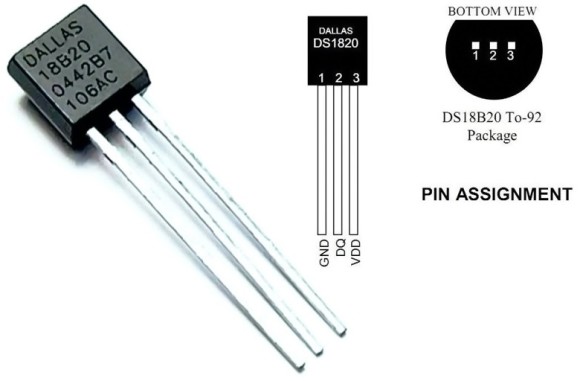

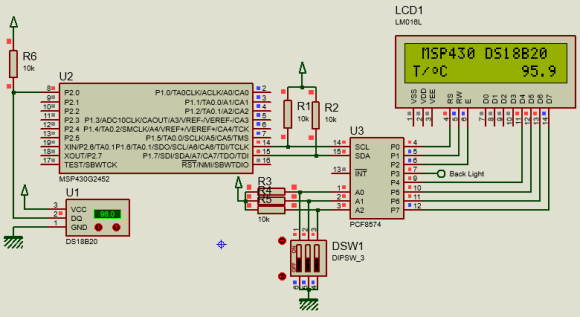

One Wire (OW) – Interfacing DS18B20 Temperature Sensor

One Wire (OW) or single wire communication is different from other more common and conventional communication platforms like SPI or I2C in terms of data exchange behavior. OW communication is also not very much popular compared to SPI, UART (RS232), I2C, RS485, etc. From device to device, the way of exchanging data varies but what’s common is the fact that all devices that use this communication method use a sort of time-slotting mechanism. Ones and zeros are defined by high pulse time over a fixed period. This trick is widely used in infrared remote controllers. One major advantage of OW communication is the fact that no special or dedicated hardware block is needed to implement it. All that is typically needed is a digital I/O pin. A timer can be used for tracking time-slots but it is optional. External interrupts can also be optionally used alongside the timer. DS18B20 one wire digital temperature sensor from Dallas semiconductor uses this communication protocol.

Code Example

one_wire.h

#include <msp430.h>

#include "delay.h"

#define DS18B20_DIR P2DIR

#define DS18B20_OUT_PORT P2OUT

#define DS18B20_IN_PORT P2IN

#define DS18B20_PIN BIT0

#define DS18B20_OUTPUT() do{DS18B20_DIR |= DS18B20_PIN;}while(0)

#define DS18B20_INPUT() do{DS18B20_DIR &= ~DS18B20_PIN;}while(0)

#define DS18B20_IN() (DS18B20_IN_PORT & DS18B20_PIN)

#define DS18B20_OUT_LOW() do{DS18B20_OUT_PORT &= ~DS18B20_PIN;}while(0)

#define DS18B20_OUT_HIGH() do{DS18B20_OUT_PORT |= DS18B20_PIN;}while(0)

#define TRUE 1

#define FALSE 0

unsigned char onewire_reset(void);

void onewire_write_bit(unsigned char bit_value);

unsigned char onewire_read_bit(void);

void onewire_write(unsigned char value);

unsigned char onewire_read(void);

one_wire.c

#include "one_wire.h"

unsigned char onewire_reset(void)

{

unsigned char res = FALSE;

DS18B20_OUTPUT();

DS18B20_OUT_LOW();

delay_us(480);

DS18B20_OUT_HIGH();

delay_us(60);

DS18B20_INPUT();

res = DS18B20_IN();

delay_us(480);

return res;

}

void onewire_write_bit(unsigned char bit_value)

{

DS18B20_OUTPUT();

DS18B20_OUT_LOW();

if(bit_value)

{

delay_us(104);

DS18B20_OUT_HIGH();

}

}

unsigned char onewire_read_bit(void)

{

DS18B20_OUTPUT();

DS18B20_OUT_LOW();

DS18B20_OUT_HIGH();

delay_us(15);

DS18B20_INPUT();

return(DS18B20_IN());

}

void onewire_write(unsigned char value)

{

unsigned char s = 0;

DS18B20_OUTPUT();

while(s < 8)

{

if((value & (1 << s)))

{

DS18B20_OUT_LOW();

_delay_cycles(1);

DS18B20_OUT_HIGH();

delay_us(60);

}

else

{

DS18B20_OUT_LOW();

delay_us(60);

DS18B20_OUT_HIGH();

_delay_cycles(1);

}

s++;

}

}

unsigned char onewire_read(void)

{

unsigned char s = 0x00;

unsigned char value = 0x00;

while(s < 8)

{

DS18B20_OUTPUT();

DS18B20_OUT_LOW();

_delay_cycles(1);

DS18B20_OUT_HIGH();

DS18B20_INPUT();

if(DS18B20_IN())

{

value |= (1 << s);

}

delay_us(60);

s++;

}

return value;

}

DS18B20.h

#include <msp430.h>

#include "delay.h"

#include "one_wire.h"

#define convert_T 0x44

#define read_scratchpad 0xBE

#define write_scratchpad 0x4E

#define copy_scratchpad 0x48

#define recall_E2 0xB8

#define read_power_supply 0xB4

#define skip_ROM 0xCC

#define resolution 12

void DS18B20_init(void);

float DS18B20_get_temperature(void);

DS18B20.c

#include "DS18B20.h"

void DS18B20_init(void)

{

onewire_reset();

delay_ms(100);

}

float DS18B20_get_temperature(void)

{

unsigned char msb = 0x00;

unsigned char lsb = 0x00;

register float temp = 0.0;

onewire_reset();

onewire_write(skip_ROM);

onewire_write(convert_T);

switch(resolution)

{

case 12:

{

delay_ms(750);

break;

}

case 11:

{

delay_ms(375);

break;

}

case 10:

{

delay_ms(188);

break;

}

case 9:

{

delay_ms(94);

break;

}

}

onewire_reset();

onewire_write(skip_ROM);

onewire_write(read_scratchpad);

lsb = onewire_read();

msb = onewire_read();

temp = msb;

temp *= 256.0;

temp += lsb;

switch(resolution)

{

case 12:

{

temp *= 0.0625;

break;

}

case 11:

{

temp *= 0.125;

break;

}

case 10:

{

temp *= 0.25;

break;

}

case 9:

{

temp *= 0.5;

break;

}

}

delay_ms(40);

return (temp);

}

main.c

#include <msp430.h>

#include "delay.h"

#include "SW_I2C.h"

#include "PCF8574.h"

#include "one_wire.h"

#include "DS18B20.h"

#include "lcd.h"

const unsigned char symbol[8] =

{

0x00, 0x06, 0x09, 0x09, 0x06, 0x00, 0x00, 0x00

};

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

void lcd_symbol(void);

void print_C(unsigned char x_pos, unsigned char y_pos, signed int value);

void print_I(unsigned char x_pos, unsigned char y_pos, signed long value);

void print_D(unsigned char x_pos, unsigned char y_pos, signed int value, unsigned char points);

void print_F(unsigned char x_pos, unsigned char y_pos, float value, unsigned char points);

void main(void)

{

float t = 0.0;

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();

/* initialize Config for the MSP430 WDT+ */

WDTplus_graceInit();

DS18B20_init();

LCD_init();

lcd_symbol();

LCD_goto(1, 0);

LCD_putstr("MSP430 DS18B20");

LCD_goto(0, 1);

LCD_putstr("T/ C");

LCD_goto(2, 1);

LCD_send(0, DAT);

while(1)

{

t = DS18B20_get_temperature();

print_F(9, 1, t, 3);

delay_ms(1000);

};

}

void GPIO_graceInit(void)

{

/* USER CODE START (section: GPIO_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: GPIO_graceInit_prologue) */

/* Port 1 Output Register */

P1OUT = 0;

/* Port 1 Direction Register */

P1DIR = 0;

/* Port 1 Interrupt Edge Select Register */

P1IES = 0;

/* Port 1 Interrupt Flag Register */

P1IFG = 0;

/* Port 2 Output Register */

P2OUT = 0;

/* Port 2 Port Select Register */

P2SEL &= ~(BIT6 | BIT7);

/* Port 2 Direction Register */

P2DIR = 0;

/* Port 2 Interrupt Edge Select Register */

P2IES = 0;

/* Port 2 Interrupt Flag Register */

P2IFG = 0;

/* USER CODE START (section: GPIO_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: GPIO_graceInit_epilogue) */

}

void BCSplus_graceInit(void)

{

/* USER CODE START (section: BCSplus_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: BCSplus_graceInit_prologue) */

/*

* Basic Clock System Control 2

*

* SELM_0 -- DCOCLK

* DIVM_0 -- Divide by 1

* ~SELS -- DCOCLK

* DIVS_0 -- Divide by 1

* ~DCOR -- DCO uses internal resistor

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

BCSCTL2 = SELM_0 | DIVM_0 | DIVS_0;

if (CALBC1_8MHZ != 0xFF)

{

/* Adjust this accordingly to your VCC rise time */

__delay_cycles(100000);

// Follow recommended flow. First, clear all DCOx and MODx bits. Then

// apply new RSELx values. Finally, apply new DCOx and MODx bit values.

DCOCTL = 0x00;

BCSCTL1 = CALBC1_8MHZ; /* Set DCO to 8MHz */

DCOCTL = CALDCO_8MHZ;

}

/*

* Basic Clock System Control 1

*

* XT2OFF -- Disable XT2CLK

* ~XTS -- Low Frequency

* DIVA_0 -- Divide by 1

*

* Note: ~XTS indicates that XTS has value zero

*/

BCSCTL1 |= XT2OFF | DIVA_0;

/*

* Basic Clock System Control 3

*

* XT2S_0 -- 0.4 - 1 MHz

* LFXT1S_0 -- If XTS = 0, XT1 = 32768kHz Crystal ; If XTS = 1, XT1 = 0.4 - 1-MHz crystal or resonator

* XCAP_1 -- ~6 pF

*/

BCSCTL3 = XT2S_0 | LFXT1S_0 | XCAP_1;

/* USER CODE START (section: BCSplus_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: BCSplus_graceInit_epilogue) */

}

void System_graceInit(void)

{

/* USER CODE START (section: System_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: System_graceInit_prologue) */

/*

* SR, Status Register

*

* ~SCG1 -- Disable System clock generator 1

* ~SCG0 -- Disable System clock generator 0

* ~OSCOFF -- Oscillator On

* ~CPUOFF -- CPU On

* GIE -- General interrupt enable

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

__bis_SR_register(GIE);

/* USER CODE START (section: System_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: System_graceInit_epilogue) */

}

void WDTplus_graceInit(void)

{

/* USER CODE START (section: RTC_B_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: RTC_B_graceInit_prologue) */

/*

* WDTCTL, Watchdog Timer+ Register

*

* WDTPW -- Watchdog password

* WDTHOLD -- Watchdog timer+ is stopped

* ~WDTNMIES -- NMI on rising edge

* ~WDTNMI -- Reset function

* ~WDTTMSEL -- Watchdog mode

* ~WDTCNTCL -- No action

* ~WDTSSEL -- SMCLK

* ~WDTIS0 -- Watchdog clock source bit0 disabled

* ~WDTIS1 -- Watchdog clock source bit1 disabled

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

WDTCTL = WDTPW | WDTHOLD;

/* USER CODE START (section: RTC_B_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: RTC_B_graceInit_epilogue) */

}

void lcd_symbol(void)

{

unsigned char s = 0;

LCD_send(0x40, CMD);

for(s = 0; s < 8; s++)

{

LCD_send(symbol[s], DAT);

}

LCD_send(0x80, CMD);

}

void print_C(unsigned char x_pos, unsigned char y_pos, signed int value)

{

char ch[5] = {0x20, 0x20, 0x20, 0x20, '\0'};

if(value < 0x00)

{

ch[0] = 0x2D;

value = -value;

}

else

{

ch[0] = 0x20;

}

if((value > 99) && (value <= 999))

{

ch[1] = ((value / 100) + 0x30);

ch[2] = (((value % 100) / 10) + 0x30);

ch[3] = ((value % 10) + 0x30);

}

else if((value > 9) && (value <= 99))

{

ch[1] = (((value % 100) / 10) + 0x30);

ch[2] = ((value % 10) + 0x30);

ch[3] = 0x20;

}

else if((value >= 0) && (value <= 9))

{

ch[1] = ((value % 10) + 0x30);

ch[2] = 0x20;

ch[3] = 0x20;

}

LCD_goto(x_pos, y_pos);

LCD_putstr(ch);

}

void print_I(unsigned char x_pos, unsigned char y_pos, signed long value)

{

char ch[7] = {0x20, 0x20, 0x20, 0x20, 0x20, 0x20, '\0'};

if(value < 0)

{

ch[0] = 0x2D;

value = -value;

}

else

{

ch[0] = 0x20;

}

if(value > 9999)

{

ch[1] = ((value / 10000) + 0x30);

ch[2] = (((value % 10000)/ 1000) + 0x30);

ch[3] = (((value % 1000) / 100) + 0x30);

ch[4] = (((value % 100) / 10) + 0x30);

ch[5] = ((value % 10) + 0x30);

}

else if((value > 999) && (value <= 9999))

{

ch[1] = (((value % 10000)/ 1000) + 0x30);

ch[2] = (((value % 1000) / 100) + 0x30);

ch[3] = (((value % 100) / 10) + 0x30);

ch[4] = ((value % 10) + 0x30);

ch[5] = 0x20;

}

else if((value > 99) && (value <= 999))

{

ch[1] = (((value % 1000) / 100) + 0x30);

ch[2] = (((value % 100) / 10) + 0x30);

ch[3] = ((value % 10) + 0x30);

ch[4] = 0x20;

ch[5] = 0x20;

}

else if((value > 9) && (value <= 99))

{

ch[1] = (((value % 100) / 10) + 0x30);

ch[2] = ((value % 10) + 0x30);

ch[3] = 0x20;

ch[4] = 0x20;

ch[5] = 0x20;

}

else

{

ch[1] = ((value % 10) + 0x30);

ch[2] = 0x20;

ch[3] = 0x20;

ch[4] = 0x20;

ch[5] = 0x20;

}

LCD_goto(x_pos, y_pos);

LCD_putstr(ch);

}

void print_D(unsigned char x_pos, unsigned char y_pos, signed int value, unsigned char points)

{

char ch[5] = {0x2E, 0x20, 0x20, '\0'};

ch[1] = ((value / 100) + 0x30);

if(points > 1)

{

ch[2] = (((value / 10) % 10) + 0x30);

if(points > 1)

{

ch[3] = ((value % 10) + 0x30);

}

}

LCD_goto(x_pos, y_pos);

LCD_putstr(ch);

}

void print_F(unsigned char x_pos, unsigned char y_pos, float value, unsigned char points)

{

signed long tmp = 0x0000;

tmp = value;

print_I(x_pos, y_pos, tmp);

tmp = ((value - tmp) * 1000);

if(tmp < 0)

{

tmp = -tmp;

}

if(value < 0)

{

value = -value;

LCD_goto(x_pos, y_pos);

LCD_putchar(0x2D);

}

else

{

LCD_goto(x_pos, y_pos);

LCD_putchar(0x20);

}

if((value >= 10000) && (value < 100000))

{

print_D((x_pos + 6), y_pos, tmp, points);

}

else if((value >= 1000) && (value < 10000))

{

print_D((x_pos + 5), y_pos, tmp, points);

}

else if((value >= 100) && (value < 1000))

{

print_D((x_pos + 4), y_pos, tmp, points);

}

else if((value >= 10) && (value < 100))

{

print_D((x_pos + 3), y_pos, tmp, points);

}

else if(value < 10)

{

print_D((x_pos + 2), y_pos, tmp, points);

}

}

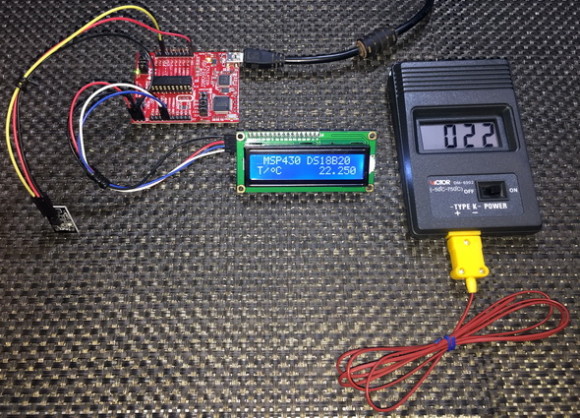

Simulation

Explanation

One wire communication is detailed in these application notes from Maxim:

https://www.maximintegrated.com/en/app-notes/index.mvp/id/126

https://www.maximintegrated.com/en/app-notes/index.mvp/id/162

These notes are all that are needed for implementing the one wire communication interface for DS18B20. Please go through these notes for details. The codes are self-explanatory and are implemented from the code examples in these app notes.

Demo

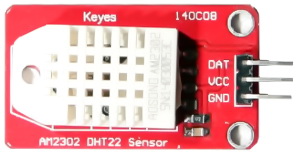

One Wire (OW) – Interfacing DHT22 Hygrometer Sensor

Like DS18B20, DHT22 (a.k.a AM2302) digital relative humidity-temperature or hygrometer sensor uses time-slotting principle over one wire to transfer data to its host controller. Apart from other technical specs, these sensors differ in terms of time-slots and in the process of data exchanging and communication bus arbitration. Since data is transferred digitally over one wire, there is no need for such sensors to be present on board and close to the host MCU. Thus, such sensors can be placed significantly far from the host micro. This is not so easily possible with analog sensors or with sensors using multiple wires. This feature is what makes OW communication method an impressive one.

Code Example

DHT22.h

#include <msp430.h>

#include <delay.h>

#define DHT22_DIR P2DIR

#define DHT22_OUT_PORT P2OUT

#define DHT22_IN_PORT P2IN

#define DHT22_PIN BIT0

#define DHT22_DIR_OUT() do{DHT22_DIR |= DHT22_PIN;}while(0)

#define DHT22_DIR_IN() do{DHT22_DIR &= ~DHT22_PIN;}while(0)

#define DHT22_IN() (DHT22_IN_PORT & DHT22_PIN)

#define DHT22_OUT_LOW() do{DHT22_OUT_PORT &= ~DHT22_PIN;}while(0)

#define DHT22_OUT_HIGH() do{DHT22_OUT_PORT |= DHT22_PIN;}while(0)

#define TRUE 1

#define FALSE 0

extern unsigned char values[5];

void DHT22_init(void);

unsigned char DHT22_get_byte(void);

unsigned char DHT22_get_data(void);

DHT22.c

#include "DHT22.h"

unsigned char values[5];

void DHT22_init(void)

{

DHT22_DIR_IN();

delay_ms(1000);

}

unsigned char DHT22_get_byte(void)

{

unsigned char s = 8;

unsigned char value = 0;

DHT22_DIR_IN();

while(s > 0)

{

value <<= 1;

while(DHT22_IN() == FALSE);

delay_us(30);

if(DHT22_IN())

{

value |= 1;

}

while(DHT22_IN());

s--;

}

return value;

}

unsigned char DHT22_get_data(void)

{

unsigned char chk = FALSE;

unsigned char s = 0;

unsigned char check_sum = 0;

DHT22_DIR_OUT();

DHT22_OUT_HIGH();

DHT22_OUT_LOW();

delay_ms(1);

DHT22_OUT_HIGH();

delay_us(32);

DHT22_DIR_IN();

chk = DHT22_IN();

delay_us(2);

if(chk == TRUE)

{

return 1;

}

delay_us(80);

chk = DHT22_IN();

if(chk == FALSE)

{

return 2;

}

delay_us(80);

for(s = 0; s <= 4; s += 1)

{

values[s] = DHT22_get_byte();

}

DHT22_DIR_OUT();

DHT22_OUT_HIGH();

for(s = 0; s < 4; s++)

{

check_sum += values[s];

}

if(check_sum != values[4])

{

return 3;

}

else

{

return 0;

}

}

main.c

#include <msp430.h>

#include "delay.h"

#include "SW_I2C.h"

#include "PCF8574.h"

#include "lcd.h"

#include "DHT22.h"

const unsigned char symbol[8] =

{

0x00, 0x06, 0x09, 0x09, 0x06, 0x00, 0x00, 0x00

};

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

void lcd_symbol(void);

void print_C(unsigned char x_pos, unsigned char y_pos, signed int value);

void print_I(unsigned char x_pos, unsigned char y_pos, signed long value);

void print_D(unsigned char x_pos, unsigned char y_pos, signed int value, unsigned char points);

void print_F(unsigned char x_pos, unsigned char y_pos, float value, unsigned char points);

void main(void)

{

float value = 0.0;

unsigned char state = 0;

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();

/* initialize Config for the MSP430 WDT+ */

WDTplus_graceInit();

DHT22_init();

LCD_init();

lcd_symbol();

while(1)

{

state = DHT22_get_data();

switch(state)

{

case 1:

{

LCD_goto(0, 0);

LCD_putstr("No Sensor Found!");

LCD_goto(0, 1);

LCD_putstr(" ");

break;

}

case 2:

{

LCD_goto(0, 0);

LCD_putstr("Checksum Error!");

LCD_goto(0, 1);

LCD_putstr(" ");

break;

}

default:

{

value = ((values[0] * 256.0 + values[1]) * 0.1);

LCD_goto(0, 0);

LCD_putstr("R.H/%: ");

print_F(11, 0, value, 1);

value = ((values[2] * 256.0 + values[3]) * 0.1);

LCD_goto(0, 1);

LCD_putstr("T/ C : ");

LCD_goto(2, 1);

LCD_send(0, DAT);

print_F(11, 1, value, 1);

break;

}

}

delay_ms(1000);

};

}

void GPIO_graceInit(void)

{

/* USER CODE START (section: GPIO_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: GPIO_graceInit_prologue) */

/* Port 1 Output Register */

P1OUT = 0;

/* Port 1 Direction Register */

P1DIR = 0;

/* Port 1 Interrupt Edge Select Register */

P1IES = 0;

/* Port 1 Interrupt Flag Register */

P1IFG = 0;

/* Port 2 Output Register */

P2OUT = 0;

/* Port 2 Port Select Register */

P2SEL &= ~(BIT6 | BIT7);

/* Port 2 Direction Register */

P2DIR = 0;

/* Port 2 Interrupt Edge Select Register */

P2IES = 0;

/* Port 2 Interrupt Flag Register */

P2IFG = 0;

/* USER CODE START (section: GPIO_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: GPIO_graceInit_epilogue) */

}

void BCSplus_graceInit(void)

{

/* USER CODE START (section: BCSplus_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: BCSplus_graceInit_prologue) */

/*

* Basic Clock System Control 2

*

* SELM_0 -- DCOCLK

* DIVM_0 -- Divide by 1

* ~SELS -- DCOCLK

* DIVS_0 -- Divide by 1

* ~DCOR -- DCO uses internal resistor

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

BCSCTL2 = SELM_0 | DIVM_0 | DIVS_0;

if (CALBC1_8MHZ != 0xFF)

{

/* Adjust this accordingly to your VCC rise time */

__delay_cycles(100000);

// Follow recommended flow. First, clear all DCOx and MODx bits. Then

// apply new RSELx values. Finally, apply new DCOx and MODx bit values.

DCOCTL = 0x00;

BCSCTL1 = CALBC1_8MHZ; /* Set DCO to 8MHz */

DCOCTL = CALDCO_8MHZ;

}

/*

* Basic Clock System Control 1

*

* XT2OFF -- Disable XT2CLK

* ~XTS -- Low Frequency

* DIVA_0 -- Divide by 1

*

* Note: ~XTS indicates that XTS has value zero

*/

BCSCTL1 |= XT2OFF | DIVA_0;

/*

* Basic Clock System Control 3

*

* XT2S_0 -- 0.4 - 1 MHz

* LFXT1S_0 -- If XTS = 0, XT1 = 32768kHz Crystal ; If XTS = 1, XT1 = 0.4 - 1-MHz crystal or resonator

* XCAP_1 -- ~6 pF

*/

BCSCTL3 = XT2S_0 | LFXT1S_0 | XCAP_1;

/* USER CODE START (section: BCSplus_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: BCSplus_graceInit_epilogue) */

}

void System_graceInit(void)

{

/* USER CODE START (section: System_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: System_graceInit_prologue) */

/*

* SR, Status Register

*

* ~SCG1 -- Disable System clock generator 1

* ~SCG0 -- Disable System clock generator 0

* ~OSCOFF -- Oscillator On

* ~CPUOFF -- CPU On

* GIE -- General interrupt enable

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

__bis_SR_register(GIE);

/* USER CODE START (section: System_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: System_graceInit_epilogue) */

}

void WDTplus_graceInit(void)

{

/* USER CODE START (section: RTC_B_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: RTC_B_graceInit_prologue) */

/*

* WDTCTL, Watchdog Timer+ Register

*

* WDTPW -- Watchdog password

* WDTHOLD -- Watchdog timer+ is stopped

* ~WDTNMIES -- NMI on rising edge

* ~WDTNMI -- Reset function

* ~WDTTMSEL -- Watchdog mode

* ~WDTCNTCL -- No action

* ~WDTSSEL -- SMCLK

* ~WDTIS0 -- Watchdog clock source bit0 disabled

* ~WDTIS1 -- Watchdog clock source bit1 disabled

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

WDTCTL = WDTPW | WDTHOLD;

/* USER CODE START (section: RTC_B_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: RTC_B_graceInit_epilogue) */

}

void lcd_symbol(void)

{

unsigned char s = 0;

LCD_send(0x40, CMD);

for(s = 0; s < 8; s++)

{

LCD_send(symbol[s], DAT);

}

LCD_send(0x80, CMD);

}

void print_C(unsigned char x_pos, unsigned char y_pos, signed int value)

{

char ch[5] = {0x20, 0x20, 0x20, 0x20, '\0'};

if(value < 0x00)

{

ch[0] = 0x2D;

value = -value;

}

else

{

ch[0] = 0x20;

}

if((value > 99) && (value <= 999))

{

ch[1] = ((value / 100) + 0x30);

ch[2] = (((value % 100) / 10) + 0x30);

ch[3] = ((value % 10) + 0x30);

}

else if((value > 9) && (value <= 99))

{

ch[1] = (((value % 100) / 10) + 0x30);

ch[2] = ((value % 10) + 0x30);

ch[3] = 0x20;

}

else if((value >= 0) && (value <= 9))

{

ch[1] = ((value % 10) + 0x30);

ch[2] = 0x20;

ch[3] = 0x20;

}

LCD_goto(x_pos, y_pos);

LCD_putstr(ch);

}

void print_I(unsigned char x_pos, unsigned char y_pos, signed long value)

{

char ch[7] = {0x20, 0x20, 0x20, 0x20, 0x20, 0x20, '\0'};

if(value < 0)

{

ch[0] = 0x2D;

value = -value;

}

else

{

ch[0] = 0x20;

}

if(value > 9999)

{

ch[1] = ((value / 10000) + 0x30);

ch[2] = (((value % 10000)/ 1000) + 0x30);

ch[3] = (((value % 1000) / 100) + 0x30);

ch[4] = (((value % 100) / 10) + 0x30);

ch[5] = ((value % 10) + 0x30);

}

else if((value > 999) && (value <= 9999))

{

ch[1] = (((value % 10000)/ 1000) + 0x30);

ch[2] = (((value % 1000) / 100) + 0x30);

ch[3] = (((value % 100) / 10) + 0x30);

ch[4] = ((value % 10) + 0x30);

ch[5] = 0x20;

}

else if((value > 99) && (value <= 999))

{

ch[1] = (((value % 1000) / 100) + 0x30);

ch[2] = (((value % 100) / 10) + 0x30);

ch[3] = ((value % 10) + 0x30);

ch[4] = 0x20;

ch[5] = 0x20;

}

else if((value > 9) && (value <= 99))

{

ch[1] = (((value % 100) / 10) + 0x30);

ch[2] = ((value % 10) + 0x30);

ch[3] = 0x20;

ch[4] = 0x20;

ch[5] = 0x20;

}

else

{

ch[1] = ((value % 10) + 0x30);

ch[2] = 0x20;

ch[3] = 0x20;

ch[4] = 0x20;

ch[5] = 0x20;

}

LCD_goto(x_pos, y_pos);

LCD_putstr(ch);

}

void print_D(unsigned char x_pos, unsigned char y_pos, signed int value, unsigned char points)

{

char ch[5] = {0x2E, 0x20, 0x20, '\0'};

ch[1] = ((value / 100) + 0x30);

if(points > 1)

{

ch[2] = (((value / 10) % 10) + 0x30);

if(points > 1)

{

ch[3] = ((value % 10) + 0x30);

}

}

LCD_goto(x_pos, y_pos);

LCD_putstr(ch);

}

void print_F(unsigned char x_pos, unsigned char y_pos, float value, unsigned char points)

{

signed long tmp = 0x0000;

tmp = value;

print_I(x_pos, y_pos, tmp);

tmp = ((value - tmp) * 1000);

if(tmp < 0)

{

tmp = -tmp;

}

if(value < 0)

{

value = -value;

LCD_goto(x_pos, y_pos);

LCD_putchar(0x2D);

}

else

{

LCD_goto(x_pos, y_pos);

LCD_putchar(0x20);

}

if((value >= 10000) && (value < 100000))

{

print_D((x_pos + 6), y_pos, tmp, points);

}

else if((value >= 1000) && (value < 10000))

{

print_D((x_pos + 5), y_pos, tmp, points);

}

else if((value >= 100) && (value < 1000))

{

print_D((x_pos + 4), y_pos, tmp, points);

}

else if((value >= 10) && (value < 100))

{

print_D((x_pos + 3), y_pos, tmp, points);

}

else if(value < 10)

{

print_D((x_pos + 2), y_pos, tmp, points);

}

}

Explanation

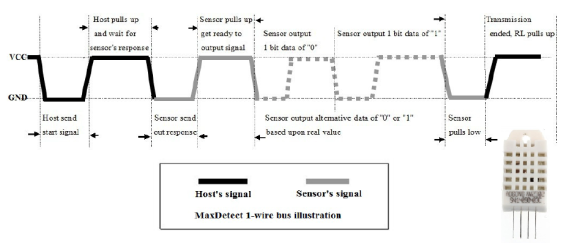

Unlike I2C, SPI, UART and other communication methods, one wire communication has no fixed communication standard. A perfect example is the difference between the way of communicating with DHT22 and DS18B20. Although they appear to share a similar methodology but the communication protocols are different.

Shown above is the timing diagram of DHT22. If you compare the timings for ones and zeroes in both devices you’ll notice that these timings are way different. Same goes for the data, command and control processes. Here again the datasheet of DHT22 is used to create the library for DHT22 and the process is just manipulation of a single GPIO pin.

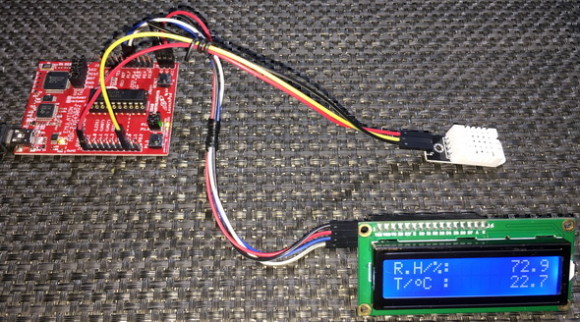

Demo

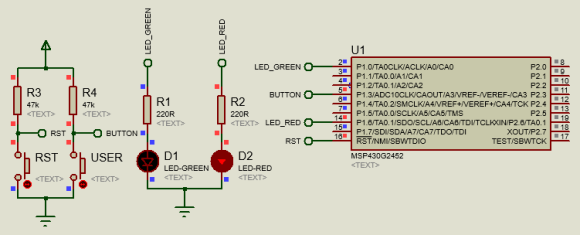

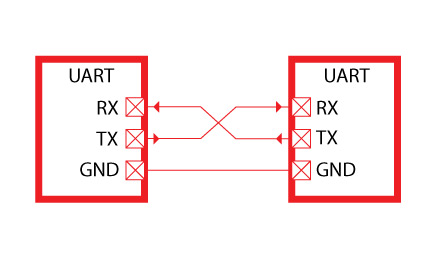

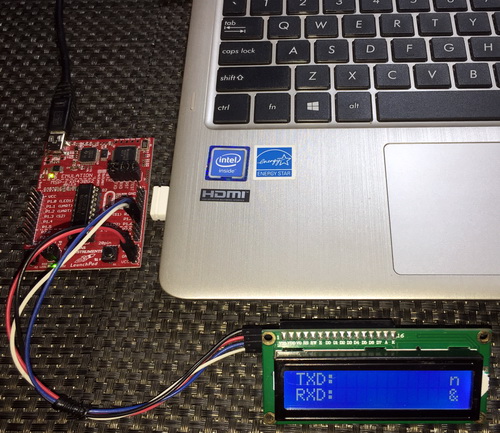

Software UART

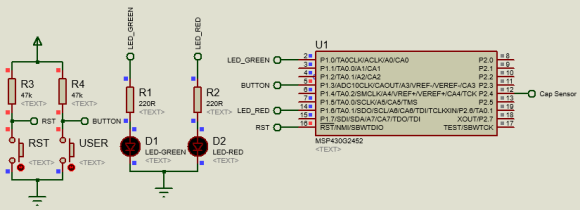

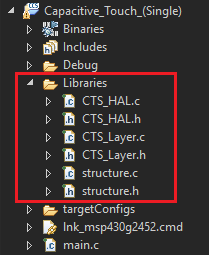

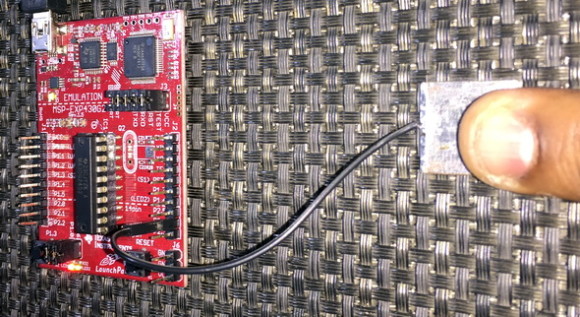

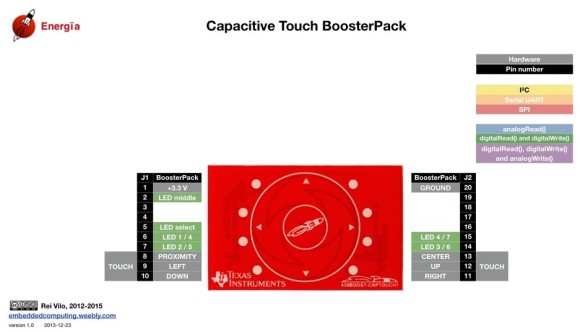

Software UART is seldom needed but it comes really useful in absence of hardware UART. In some cases, we may not have the luxury of using hardware UART. Hardware UART block may also be absent. We already know that USCI module can be used for implementing hardware UART but this block is not present in chips like MSP430G2452. In such devices, we have to use software-generated UART. Software UART uses ordinary digital I/Os and delays. Both additionally and optionally external interrupts and timers can be used for better results. Owing to its hardware independency and simplicity, it is very robust. However extra coding and therefore extra memory spaces are needed.

Code Example

SW_UART.h

#include <msp430.h>

#include "delay.h"

#define SW_UART_RXD_DIR P1DIR

#define SW_UART_TXD_DIR P1DIR

#define SW_UART_RXD_OUT P1OUT

#define SW_UART_TXD_OUT P1OUT

#define SW_UART_RXD_IN P1IN

#define SW_UART_RXD_IN_RES P1REN

#define SW_UART_RXD_PIN BIT1

#define SW_UART_TXD_PIN BIT2

#define SW_UART_RXD_DIR_IN() do{SW_UART_RXD_OUT |= SW_UART_RXD_PIN; SW_UART_RXD_DIR &= ~SW_UART_RXD_PIN; SW_UART_RXD_IN_RES |= SW_UART_RXD_PIN;}while(0)

#define SW_UART_TXD_DIR_OUT() do{SW_UART_TXD_DIR |= SW_UART_TXD_PIN;}while(0)

#define SW_UART_TXD_OUT_HIGH() do{SW_UART_TXD_OUT |= SW_UART_TXD_PIN;}while(0)

#define SW_UART_TXD_OUT_LOW() do{SW_UART_TXD_OUT &= ~SW_UART_TXD_PIN;}while(0)

#define SW_UART_RXD_INPUT() (SW_UART_RXD_IN & SW_UART_RXD_PIN)

#define baudrate 4800

#define no_of_bits 8

#define one_bit_delay (1000000 / baudrate)

#define half_bit_delay (one_bit_delay / 2)

void SW_UART_init(void);

void SW_UART_transmit(unsigned char value);

unsigned char SW_UART_receive(void);

SW_UART.c

#include "SW_UART.h"

void SW_UART_init(void)

{

SW_UART_TXD_DIR_OUT();

SW_UART_RXD_DIR_IN();

SW_UART_TXD_OUT_HIGH();

delay_ms(10);

}

void SW_UART_transmit(unsigned char value)

{

unsigned char bits = 0;

SW_UART_TXD_OUT_LOW();

delay_us(one_bit_delay);

for(bits = 0; bits < no_of_bits; bits++)

{

if((value >> bits) & 0x01)

{

SW_UART_TXD_OUT_HIGH();

}

else

{

SW_UART_TXD_OUT_LOW();

}

delay_us(one_bit_delay);

};

SW_UART_TXD_OUT_HIGH();

delay_us(one_bit_delay);

}

unsigned char SW_UART_receive(void)

{

unsigned char bits = 0;

unsigned char value = 0;

while(SW_UART_RXD_INPUT());

delay_us(one_bit_delay);

delay_us(half_bit_delay);

for(bits = 0; bits < no_of_bits; bits++)

{

if(SW_UART_RXD_INPUT())

{

value += (1 << bits);

}

delay_us(one_bit_delay);

};

if(SW_UART_RXD_INPUT())

{

delay_us(half_bit_delay);

return value;

}

else

{

delay_us(half_bit_delay);

return 0;

}

}

main.c

#include <msp430.h>

#include "delay.h"

#include "SW_I2C.h"

#include "PCF8574.h"

#include "lcd.h"

#include "SW_UART.h"

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

void main(void)

{

unsigned char rx_value = 0x00;

unsigned char tx_value = 0x20;

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();

/* initialize Config for the MSP430 WDT+ */

WDTplus_graceInit();

LCD_init();

LCD_clear_home();

LCD_goto(0, 0);

LCD_putstr("TXD:");

LCD_goto(0, 1);

LCD_putstr("RXD:");

SW_UART_init();

while(1)

{

rx_value = SW_UART_receive();

LCD_goto(15, 0);

LCD_putchar(rx_value);

tx_value++;

LCD_goto(15, 1);

LCD_putchar(tx_value);

SW_UART_transmit(tx_value);

delay_ms(200);

};

}

void GPIO_graceInit(void)

{

/* USER CODE START (section: GPIO_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: GPIO_graceInit_prologue) */

/* Port 1 Output Register */

P1OUT = 0;

/* Port 1 Direction Register */

P1DIR = 0;

/* Port 1 Interrupt Edge Select Register */

P1IES = 0;

/* Port 1 Interrupt Flag Register */

P1IFG = 0;

/* Port 2 Output Register */

P2OUT = 0;

/* Port 2 Direction Register */

P2DIR = 0;

/* Port 2 Interrupt Edge Select Register */

P2IES = 0;

/* Port 2 Interrupt Flag Register */

P2IFG = 0;

/* USER CODE START (section: GPIO_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: GPIO_graceInit_epilogue) */

}

void BCSplus_graceInit(void)

{

/* USER CODE START (section: BCSplus_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: BCSplus_graceInit_prologue) */

/*

* Basic Clock System Control 2

*

* SELM_0 -- DCOCLK

* DIVM_0 -- Divide by 1

* ~SELS -- DCOCLK

* DIVS_0 -- Divide by 1

* ~DCOR -- DCO uses internal resistor

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

BCSCTL2 = SELM_0 | DIVM_0 | DIVS_0;

if (CALBC1_8MHZ != 0xFF) {

/* Adjust this accordingly to your VCC rise time */

__delay_cycles(100000);

// Follow recommended flow. First, clear all DCOx and MODx bits. Then

// apply new RSELx values. Finally, apply new DCOx and MODx bit values.

DCOCTL = 0x00;

BCSCTL1 = CALBC1_8MHZ; /* Set DCO to 8MHz */

DCOCTL = CALDCO_8MHZ;

}

/*

* Basic Clock System Control 1

*

* XT2OFF -- Disable XT2CLK

* ~XTS -- Low Frequency

* DIVA_0 -- Divide by 1

*

* Note: ~XTS indicates that XTS has value zero

*/

BCSCTL1 |= XT2OFF | DIVA_0;

/*

* Basic Clock System Control 3

*

* XT2S_0 -- 0.4 - 1 MHz

* LFXT1S_0 -- If XTS = 0, XT1 = 32768kHz Crystal ; If XTS = 1, XT1 = 0.4 - 1-MHz crystal or resonator

* XCAP_1 -- ~6 pF

*/

BCSCTL3 = XT2S_0 | LFXT1S_0 | XCAP_1;

/* USER CODE START (section: BCSplus_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: BCSplus_graceInit_epilogue) */

}

void System_graceInit(void)

{

/* USER CODE START (section: System_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: System_graceInit_prologue) */

/*

* SR, Status Register

*

* ~SCG1 -- Disable System clock generator 1

* ~SCG0 -- Disable System clock generator 0

* ~OSCOFF -- Oscillator On

* ~CPUOFF -- CPU On

* GIE -- General interrupt enable

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

__bis_SR_register(GIE);

/* USER CODE START (section: System_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: System_graceInit_epilogue) */

}

void WDTplus_graceInit(void)

{

/* USER CODE START (section: RTC_B_graceInit_prologue) */

/* User initialization code */

/* USER CODE END (section: RTC_B_graceInit_prologue) */

/*

* WDTCTL, Watchdog Timer+ Register

*

* WDTPW -- Watchdog password

* WDTHOLD -- Watchdog timer+ is stopped

* ~WDTNMIES -- NMI on rising edge

* ~WDTNMI -- Reset function

* ~WDTTMSEL -- Watchdog mode

* ~WDTCNTCL -- No action

* ~WDTSSEL -- SMCLK

* ~WDTIS0 -- Watchdog clock source bit0 disabled

* ~WDTIS1 -- Watchdog clock source bit1 disabled

*

* Note: ~<BIT> indicates that <BIT> has value zero

*/

WDTCTL = WDTPW | WDTHOLD;

/* USER CODE START (section: RTC_B_graceInit_epilogue) */

/* User code */

/* USER CODE END (section: RTC_B_graceInit_epilogue) */

}

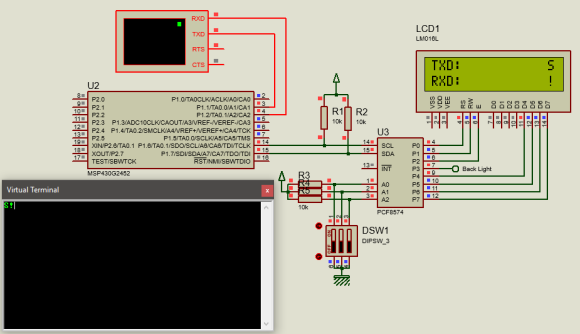

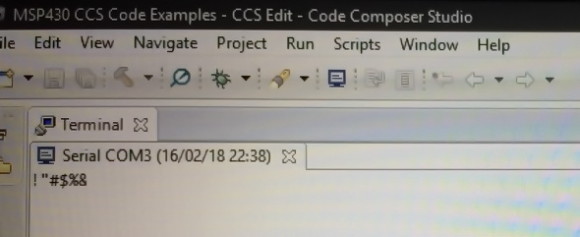

Simulation

Explanation

Software UART is created with digital I/Os. Thus, the very first task we need to do is to initialize these pins. The SW_UART header file states which pins and ports are used. So, you only need to set these first. All of my codes are modular and so once you set these properly the functions and the definitions associated take care of other tasks. This, in turn, makes the codes easily to use and ready for quick modifications/deployments.

#define SW_UART_RXD_DIR P1DIR

#define SW_UART_TXD_DIR P1DIR

#define SW_UART_RXD_OUT P1OUT

#define SW_UART_TXD_OUT P1OUT

#define SW_UART_RXD_IN P1IN

#define SW_UART_RXD_IN_RES P1REN

#define SW_UART_RXD_PIN BIT1

#define SW_UART_TXD_PIN BIT2

Once the pins are set as per requirement, it is needed to initialize them for software UART functionality.

void SW_UART_init(void)

{

SW_UART_TXD_DIR_OUT();

SW_UART_RXD_DIR_IN();

SW_UART_TXD_OUT_HIGH();

delay_ms(10);

}

The header file also states the communication baud rate and number of bits:

#define baudrate 4800

#define no_of_bits 8

#define one_bit_delay (1000000 / baudrate)

#define half_bit_delay (one_bit_delay / 2)

Based on the baud rate further timing infos are calculated. Software UART is not as reliable as hardware UART and so it is better to use low baud rates. It is even better if it can be skipped. However, when there is no other option or when there is a need for additional UART, it must be used.

The UART transmit and receive functions are written using polling methods. External digital I/O interrupt can be used for receiving data. These functions are created just by studying the signal patterns and using the same tactics as with other software communication libraries. The trick is to emulate/receive the signals as a real hardware would do.

void SW_UART_transmit(unsigned char value)

{

unsigned char bits = 0;

SW_UART_TXD_OUT_LOW();

delay_us(one_bit_delay);

for(bits = 0; bits < no_of_bits; bits++)

{

if((value >> bits) & 0x01)

{

SW_UART_TXD_OUT_HIGH();

}

else

{

SW_UART_TXD_OUT_LOW();

}

delay_us(one_bit_delay);

};

SW_UART_TXD_OUT_HIGH();

delay_us(one_bit_delay);

}

unsigned char SW_UART_receive(void)

{

unsigned char bits = 0;

unsigned char value = 0;

while(SW_UART_RXD_INPUT());

delay_us(one_bit_delay);

delay_us(half_bit_delay);

for(bits = 0; bits < no_of_bits; bits++)

{

if(SW_UART_RXD_INPUT())

{

value += (1 << bits);

}

delay_us(one_bit_delay);

};

if(SW_UART_RXD_INPUT())

{

delay_us(half_bit_delay);

return value;

}

else

{

delay_us(half_bit_delay);

return 0;

}

}

Demo

USCI SPI – Interfacing MPL115A1 Atmospheric Pressure Sensor

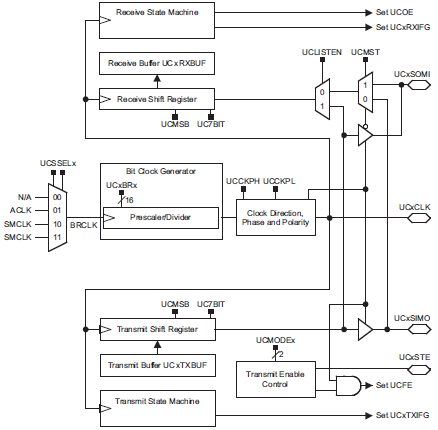

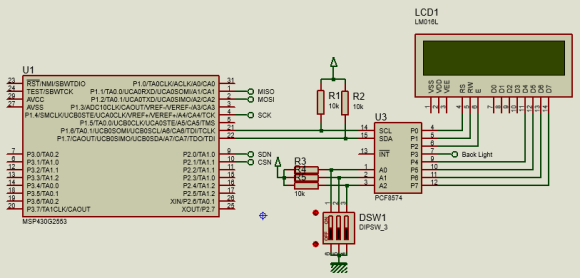

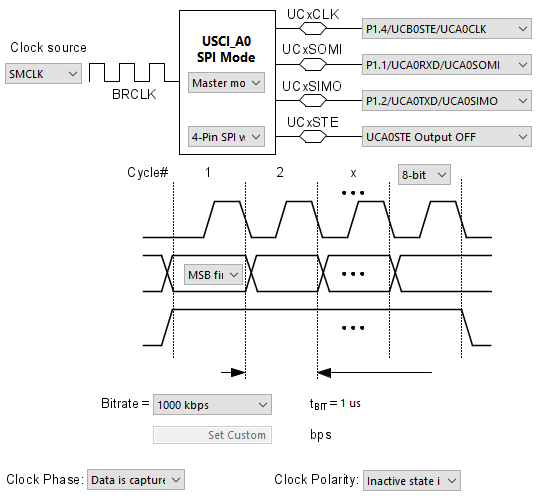

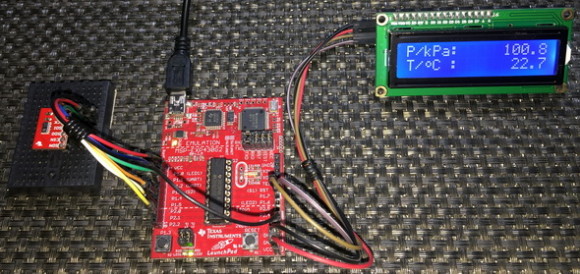

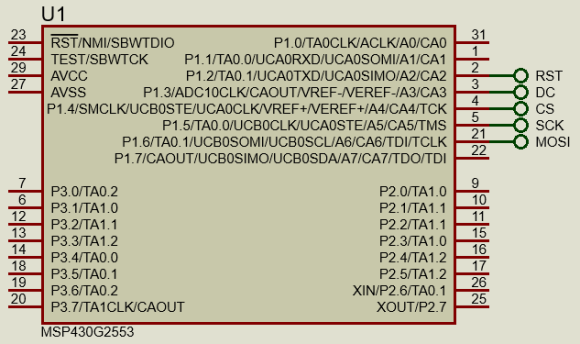

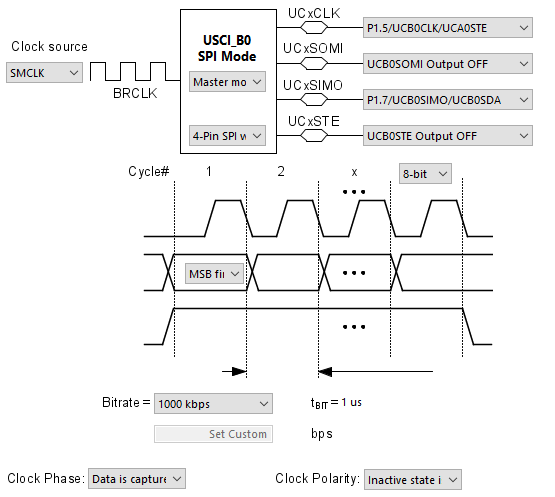

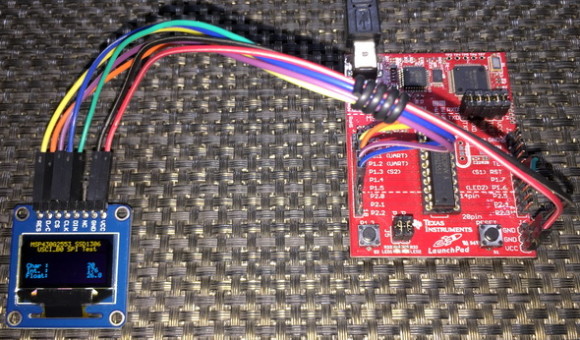

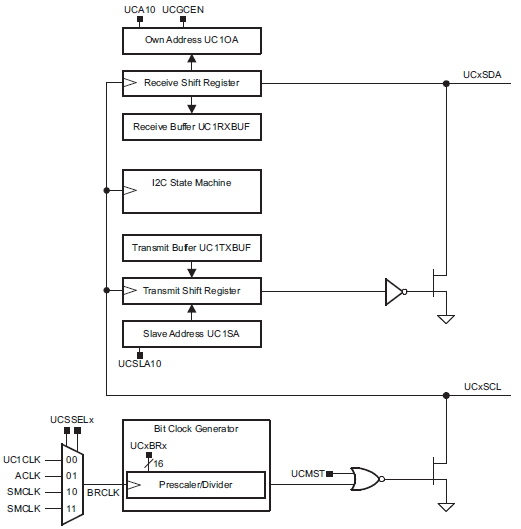

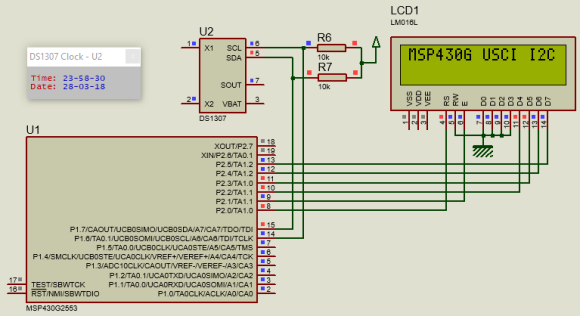

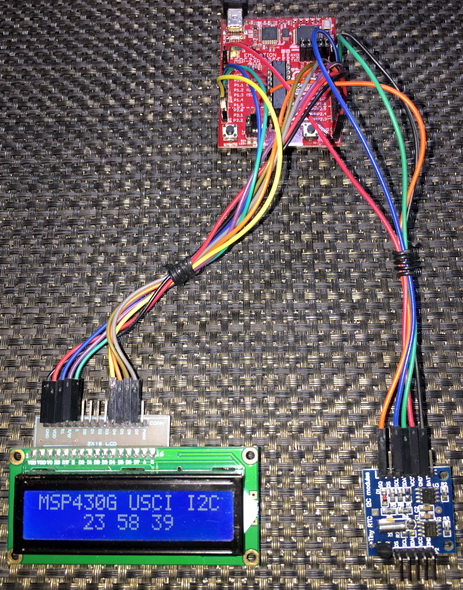

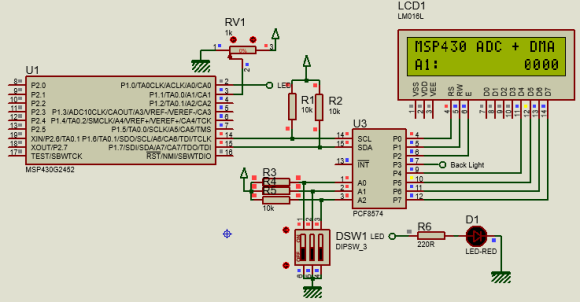

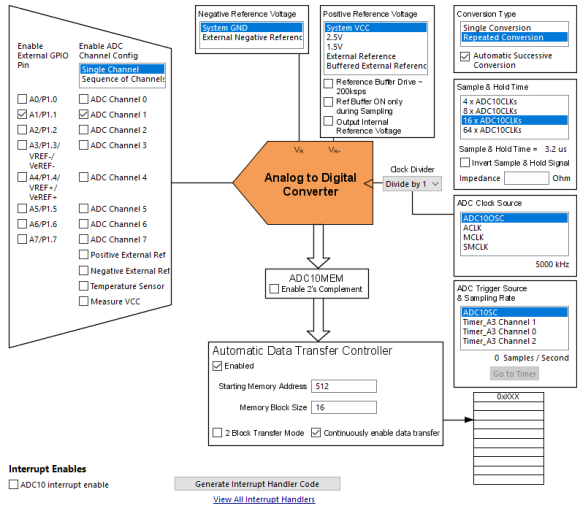

We have already seen that MSP430’s USI module can be used to implement both I2C and SPI communication platforms. However, there will be times we will have to use USCI modules. USCI is a bit complicated and is a bit difficult to use in simple terms. Here in this article, however, I kept things simple and projected ways to use this module simply. Four examples of USCI module in I2C and SPI modes will be presented in this article. The first one will demo how to interface a MSP430 device with a MPL115A1 atmospheric pressure sensor in a full-duplex SPI bus. Full-duplex SPI bus is needed the most when interfacing sensors, RTCs, SPI-based memory chips, SD cards, etc.

Code Example

HW_SPI.h

#include <msp430.h>

void HW_SPI_init(void);

void SPI_write(unsigned char tx_data);

unsigned char SPI_read(void);

unsigned char SPI_transfer(unsigned char tx_data);

HW_SPI.c

#include "HW_SPI.h"

void HW_SPI_init(void)

{

UCA0CTL1 |= UCSWRST;

UCA0CTL0 = UCCKPH | UCMSB | UCMST | UCMODE_1 | UCSYNC;

UCA0CTL1 = UCSSEL_2 | UCSWRST;

UCA0BR0 = 8;

UCA0CTL1 &= ~UCSWRST;

}

void SPI_write(unsigned char tx_data)

{

while(!(IFG2 & UCA0TXIFG));

UCA0TXBUF = tx_data;

while(UCA0STAT & UCBUSY);

}

unsigned char SPI_read(void)

{

unsigned char rx_data = 0;

while(!(IFG2 & UCA0RXIFG));

rx_data = UCA0RXBUF;

while(UCA0STAT & UCBUSY);

return rx_data;

}

unsigned char SPI_transfer(unsigned char tx_data)

{

unsigned char rx_data = 0;

while(!(IFG2 & UCA0TXIFG));

UCA0TXBUF = tx_data;

while(UCA0STAT & UCBUSY);

while(!(IFG2 & UCA0RXIFG));

rx_data = UCA0RXBUF;

while(UCA0STAT & UCBUSY);

return rx_data;

}

MPL115A1.h

#include <msp430.h>

#include "delay.h"

#include "HW_SPI.h"

#define LOW 0

#define HIGH 1

#define PRESH 0x80

#define PRESL 0x82

#define TEMPH 0x84

#define TEMPL 0x86

#define A0_H 0x88

#define A0_L 0x8A

#define B1_H 0x8C

#define B1_L 0x8E

#define B2_H 0x90

#define B2_L 0x92

#define C12_H 0x94

#define C12_L 0x96

#define conv_cmd 0x24

#define MPL115A1_CSN_PORT_OUT P2OUT

#define MPL115A1_SDN_PORT_OUT P2OUT

#define MPL115A1_CSN_PORT_DIR P2DIR

#define MPL115A1_SDN_PORT_DIR P2DIR

#define MPL115A1_SDN_pin BIT0

#define MPL115A1_CSN_pin BIT1

#define MPL115A1_SDN_HIGH() P2OUT |= MPL115A1_SDN_pin

#define MPL115A1_SDN_LOW() P2OUT &= ~MPL115A1_SDN_pin

#define MPL115A1_CSN_HIGH() P2OUT |= MPL115A1_CSN_pin

#define MPL115A1_CSN_LOW() P2OUT &= ~MPL115A1_CSN_pin

struct

{

float A0;

float B1;

float B2;

float C12;

}coefficients;

void MPL115A1_init(void);

unsigned char MPL115A1_read(unsigned char address);

void MPL115A1_write(unsigned char address, unsigned char value);

void MPL115A1_get_coefficients(void);

void MPL115A1_get_bytes(unsigned int *hb, unsigned int *lb, unsigned char address);

void MPL115A1_get_data(float *pres, float *temp);

MPL115A1.c

#include "MPL115A1.h"

void MPL115A1_init(void)

{

MPL115A1_SDN_PORT_DIR |= MPL115A1_SDN_pin;

MPL115A1_CSN_PORT_DIR |= MPL115A1_CSN_pin;

MPL115A1_SDN_HIGH();

MPL115A1_CSN_HIGH();

HW_SPI_init();

MPL115A1_get_coefficients();

}

unsigned char MPL115A1_read(unsigned char address)

{

unsigned char value = 0;

MPL115A1_CSN_LOW();

delay_ms(3);

SPI_write(address);

value = SPI_read();

value = SPI_transfer(address);

MPL115A1_CSN_HIGH();

return value;

}

void MPL115A1_write(unsigned char address, unsigned char value)

{

MPL115A1_CSN_LOW();

delay_ms(3);

SPI_write((address & 0x7F));

SPI_write(value);

MPL115A1_CSN_HIGH();

}

void MPL115A1_get_coefficients(void)

{

unsigned int hb = 0;

unsigned int lb = 0;

MPL115A1_get_bytes(&hb, &lb, A0_H);

coefficients.A0 = ((hb << 5) + (lb >> 3) + ((lb & 0x07) / 8.0));

MPL115A1_get_bytes(&hb, &lb, B1_H);

coefficients.B1 = (((((hb & 0x1F) * 0x0100) + lb) / 8192.0) - 3.0);

MPL115A1_get_bytes(&hb, &lb, B2_H);

coefficients.B2 = (((((hb - 0x80) << 8) + lb) / 16384.0) - 2.0);

MPL115A1_get_bytes(&hb, &lb, C12_H);

coefficients.C12 = (((hb * 0x100) + lb) / 16777216.0);

}

void MPL115A1_get_bytes(unsigned int *hb, unsigned int *lb, unsigned char address)

{

*hb = ((unsigned int)MPL115A1_read(address));

*lb = ((unsigned int)MPL115A1_read((address + 2)));

}

void MPL115A1_get_data(float *pres, float *temp)

{

unsigned int hb = 0;

unsigned int lb = 0;

signed long Padc = 0;

signed long Tadc = 0;

MPL115A1_write(conv_cmd, 0);

MPL115A1_get_bytes(&hb, &lb, PRESH);

Padc = (((hb << 8) + lb) >> 6);

MPL115A1_get_bytes(&hb, &lb, TEMPH);

Tadc = (((hb << 8) + lb) >> 6);

*pres = ( coefficients.A0 + (( coefficients.B1 + ( coefficients.C12 * Tadc)) * Padc) + ( coefficients.B2 * Tadc));

*pres = (((*pres * 65.0) / 1023.0) + 50.0);

*temp = (30.0 + ((Tadc - 472) / (-5.35)));

}

main.c

#include <msp430.h>

#include "delay.h"

#include "HW_SPI.h"

#include "SW_I2C.h"

#include "PCF8574.h"

#include "lcd.h"

#include "MPL115A1.h"

const unsigned char symbol[8] =

{

0x00, 0x06, 0x09, 0x09, 0x06, 0x00, 0x00, 0x00

};

void GPIO_graceInit(void);

void BCSplus_graceInit(void);

void USCI_A0_graceInit(void);

void System_graceInit(void);

void WDTplus_graceInit(void);

void lcd_symbol(void);

void print_C(unsigned char x_pos, unsigned char y_pos, signed int value);

void print_I(unsigned char x_pos, unsigned char y_pos, signed long value);

void print_D(unsigned char x_pos, unsigned char y_pos, signed int value, unsigned char points);

void print_F(unsigned char x_pos, unsigned char y_pos, float value, unsigned char points);

void main(void)

{

float t = 0.0;

float p = 0.0;

/* Stop watchdog timer from timing out during initial start-up. */

WDTCTL = WDTPW | WDTHOLD;

/* initialize Config for the MSP430 GPIO */

GPIO_graceInit();

/* initialize Config for the MSP430 2xx family clock systems (BCS) */

BCSplus_graceInit();

/* initialize Config for the MSP430 USCI_A0 */

USCI_A0_graceInit();

/* initialize Config for the MSP430 System Registers */

System_graceInit();